Extruder Belt Reduction

thingiverse

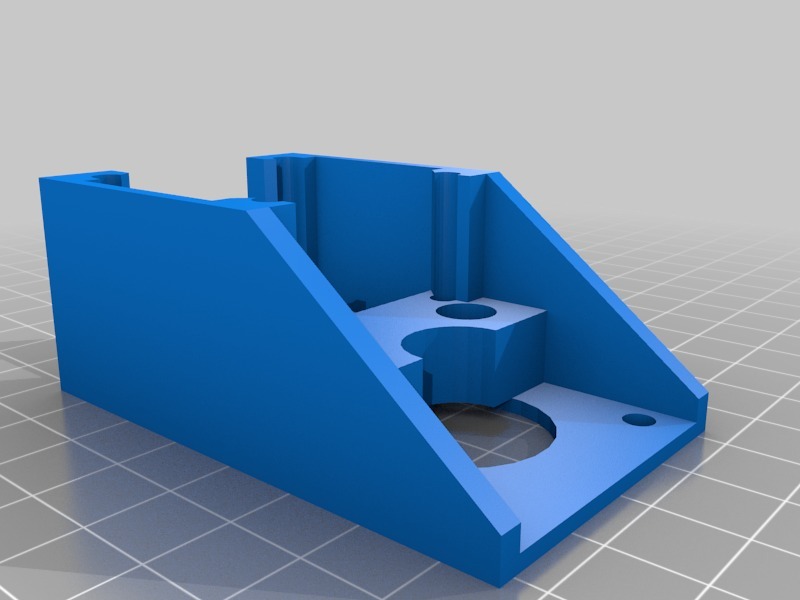

An Extruder with bowden cable faces significantly greater push resistance compared to a directly driven extruder. This increased resistance becomes even more pronounced when using a small nozzle, ultimately resulting in the stepper motor being unable to drive the filament wire efficiently. A belt-driven reduction can offer a viable solution. The Belt drive has been successfully repurposed from an RC plane with a 2:1 reduction ratio. The large wheel measures 36mm in diameter, while the smaller wheel measures 16mm outside diameter. After constructing the reduction housing, it became apparent that the belt was being rubbed against the middle mounting bolts. To address this issue, I designed and created a second part - the bearing block - which pushes the belt away from the bolts. This bearing block can be integrated into the reduction house or used separately. Bill of materials: * Big bearing in the reduction housing: 19mm outside diameter, 6mm inside diameter, and 6mm height * Bearing on the extruder: 11mm outside diameter, 5mm inside diameter, and 5mm height (glued to a print plate using epoxy) * Small bearing block: + F693ZZ 3mm x 8mm x 4mm Double Shielded Flanged Ball Bearings from BG + Shaft diameter: 3mm, length: 25mm * Other components: + F693ZZ 3mm x 8mm x 4mm Double Shielded Flanged Ball Bearings from BG (second bearing block) + MK8 All Metal Remote Extruder For 1.75mm Filament from BG + NEMA 17 26N.cm 0.4A Stepper Motor 42mm Two Phase Hybrid Stepper Motor from BG

With this file you will be able to print Extruder Belt Reduction with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Extruder Belt Reduction.