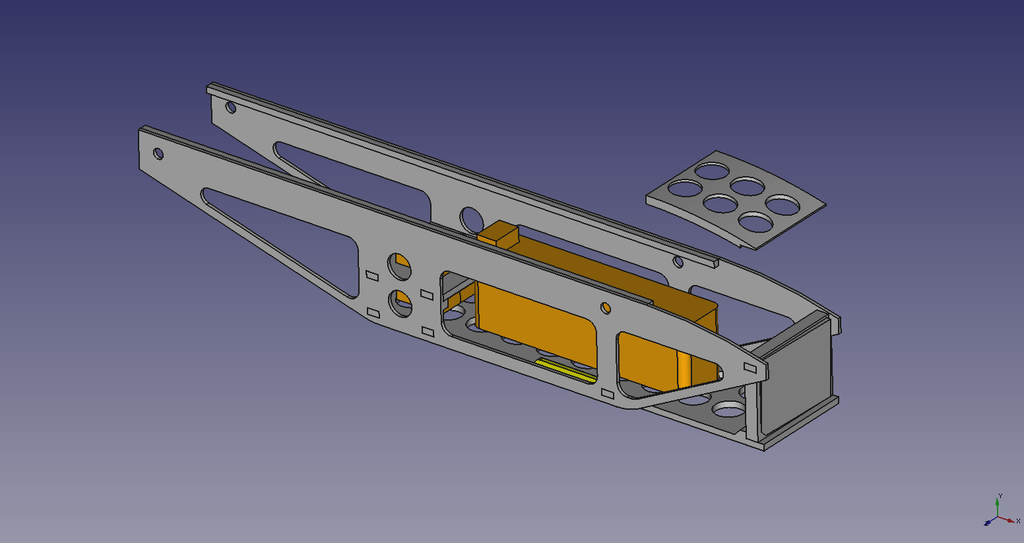

EPP EAGLE 1200mm FUSELAGE BOX

thingiverse

Enforced fuselage box for EPP EAGLE 1200 mm. Since the original wooden structure is too weak, I designed a more durable plug set. ABS is easy to sand and convenient to glue (use acetone or acetone slurry). Just in case you forgot or you are new to ABS: remember it shrinks noticeable, so you are adviced to first print a dummy along your bed’s diagonal and see how much shorter your print is, how much your ABS is really shrinking. With eSUN I needed to increase the complete set by +0,6% Otherwise the fuselage’s holes will not fit the ones in the EPP flanks. Printbed dimensons for one piece prints (L + R flanks): 180 x 280 mm This 'box' is a bit wider than the original, especially at the wings edge. It's also a bit heavier, but nothing to worry about. 9g servos Regarding the firewall: Drill the mounting holes at your convenience. The front side (motor mount side) has a down-left incidence (front view). Sand this staggered surface before setting together the kit. Did the EPP Eagle already fly? Not yet, still locked down (Dec 2020), but it surely will fly. Not a must, but you can protect your wings with optional skates (you need to cut a slit through the wing). Assembly: First put together the box and sand it. Then glue the EPP flanks to the fuselage box using instant glue, super glue, CA, CYANO, (all of them Cyanoacrylate). To faster dry the glue you may use bicarbonate: Apply CA to the parts (ABS + EPP), hold together and only then apply a little bicarbonate: it dries immediately. Same procedure with the tail, bottom and top. Use goggles, since the fumes may irritate your eyes. Take care of your fingers. Enjoy printing, building & flying! O.

With this file you will be able to print EPP EAGLE 1200mm FUSELAGE BOX with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on EPP EAGLE 1200mm FUSELAGE BOX.