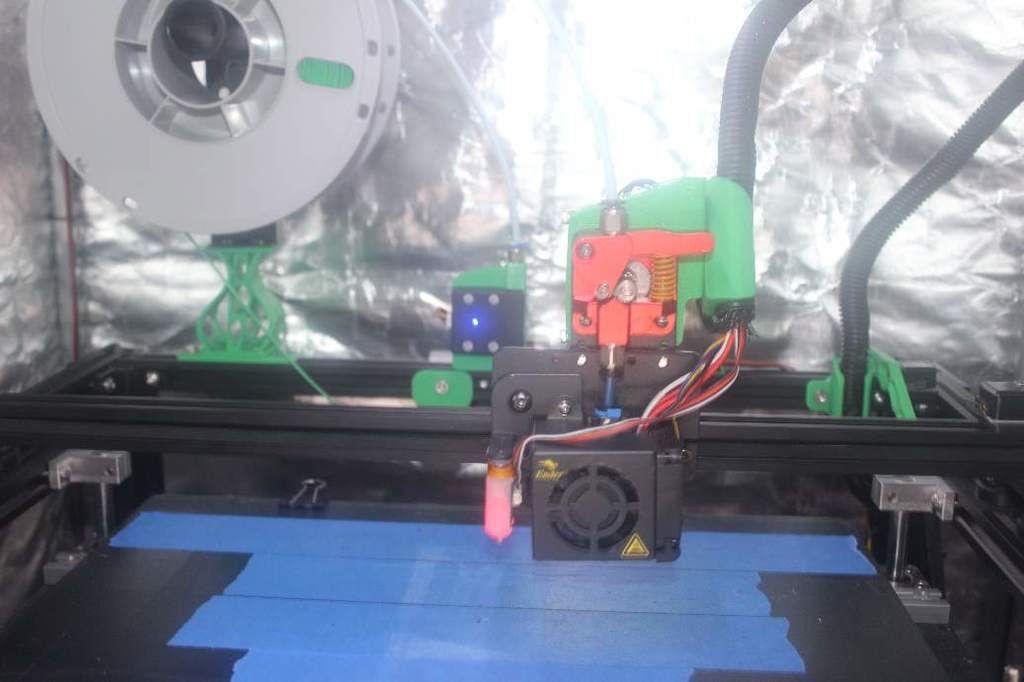

Ender 5 Plus Direct Drive Mod (Dual or Single Gear Extruder)

thingiverse

This provides a clean way to get the filament from the Filament Detector to the Extruder as well as a clean way to support the wire bundle. The wheel the filament goes around to get from the spool to the filament detector leaves enough room to easily feed the filament through the filament detector and all the way to the extruder. The Filament feeds through all the openings without any need for assistance. A gap was added above the extruder for a cleaner way to extract the Filament from the Extruder. When unloading the filament, I like to cut the filament off above the extruder to pull clean filament through the bowden tube then I heat the hot end up and extrude the remaining filament. There are parts for two different direct drive mounting brackets because I changed from the single gear drive to the double gear drive. The solid mounting plate parts are labeled "SDDPlate". The adjustable mount plate parts are labeled "ADDPlate". If you need the parts for holding the bowden tube above the extruder, there are two sized. A sort one for the single gear drive and a longer one for the double gear drive. The parts are broken up to be able to print all the parts without supports for cleaner prints. The parts the pneumatic fittings screw into for the bowden tube are different for the filament detector and extruder ends (spacing is different for alignment). The screw spacing to attach them to their parts are different to ensure they are attached to the correct mounting plates. The "C" channel for the wire bundle is the same for both locations. The 3mm spacer plate for the Extruder on the solid mounting plate is replaced my the new spacer plate with mounts for the bowden tube and cable. If you don't need a mount for the bowden tube bracket the clamps around the extruder motor with the cable holder can be used along with the spacer plate that came with the mounting place. I used M3 screws to attach the tube holders and the "C" channels. 2 screws were probably enough but I used 3 just to be safe. The screws and T-nuts that originally held the spool bracket and extruder can be re-used to hold the new spool bracket riser and filament detector mount. Two additional M4 or M5 screws with T-nuts are required to hold the bracket for the filament guide wheel and the wire bundle holder. Four additional M5 x 8mm screws are required to attach the filament spool bracket to the riser. A #6 x 1/2" screw is required to attach the filament guide roller to the bracket. Two more #6 x 1/2" screws are required if using the mount the clamps around the extruder motor. During printing the bowden tube from the filament detector and/or the wire loom may lay against the filament spool. It will not affect the operation of anything or the quality of the prints. Parts Required: (I used Socket Head Cap Screws) qty 8 to 10 - M3 x 6mm screws (I used Pan Phillips Machine Screws) qty 4 - M5 x 8mm screws (I used Socket Head Cap Screws) qty 2 - M4 or M5 x 8mm screws and T-nuts qty 1 to 3 - #6-32 x 1/2" screws (I used Socket Head Cap Screws) qty 1 - 3/8 ID x 7/8 OD x 9/32 width Pre-Lubricated Bearing (I use these because I always have some on hand) https://www.amazon.com/gp/product/B07X93RV9L/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1 This is the Direct Drive Kit with a single solid plate I ordered (this will only work with the single gear extruder) https://amazon.com/dp/B08M93Y8ZT?psc=1&ref=ppx_yo2_dt_b_product_details This is the Adjustable Direct Drive Kit I ordered (this should work with any extruder). https://amazon.com/dp/B098BFKGXL?psc=1&ref=ppx_yo2_dt_b_product_details Rev 1: Revised the Spool Riser Support and Bracket to add more support to the front of the Riser. The spool does need to sit back like I had it. The issue was a full spool of filament caused it to lean forward some. The revised version corrects that issue. I also added two M3 screws to the front of the bracket to riser attachment. Rev 2: Revised the Extruder Bracket to add space between the Bowden Tube bracket and the Extruder. Although the filament fed into the extruder without issue, when changing the filament I found I needed room to cut the end of the filament off before pulling it back through the bowden tube. Rev 3:Added additional brackets that will work with the adjustable direct drive kits that work with the single and dual gear extruders.

With this file you will be able to print Ender 5 Plus Direct Drive Mod (Dual or Single Gear Extruder) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ender 5 Plus Direct Drive Mod (Dual or Single Gear Extruder).