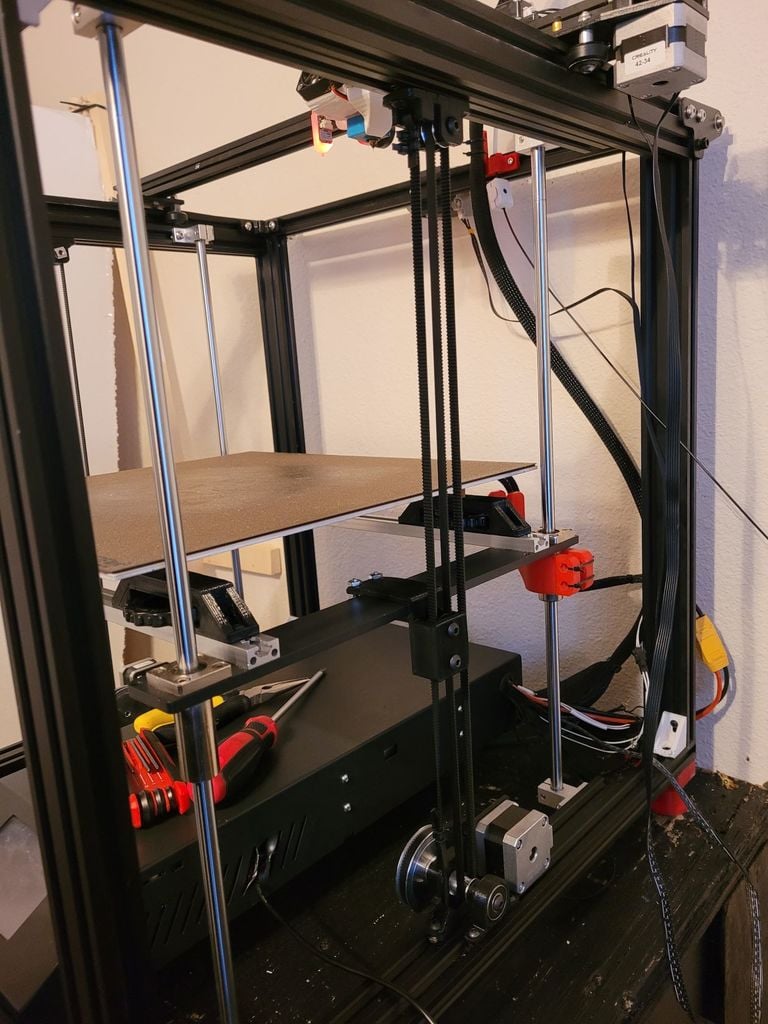

Ender 5 plus Belt Driven Z-Axis Mod

thingiverse

The 20t to 80t pulley gear reduction. This eliminates the need for a worm gear for gear reduction which eleminates backlash and reduces cost. I tried 20x60t pulleys but the gear reduction wasn't enought to keep the bed from falling. The 80t gt2 pulleys keep it from falling but it still drops a small amount and loses position on power down. My goal is better print quality and I'm not worried about power outages. I think I have a way of making it work but I haven't fleshed it out yet. !!!Must Read!!! You must use this mod https://www.thingiverse.com/thing:3890803 to raise the 5 plus bed up to make clearance for the bracket that connects the belts to the bed and make room for the top pulley bracket. Z movemet will be reduced to about 370mm. I don't see a way around this loss without redesigning the entire bed-frame structure. Your thoughts are appreciated regarding this problem. Parts: The original motor mounts are used but orientation is changed. **All parts are 5mm bore** 2x M5x50 4x M5x30 4xGT2 20tooth 2x200mm timing belts 2xGT2 60tooth 2xGT2 toothed idler pulley 4xsmooth idler pulley zip ties 4x608 bearings. I know 605 would be better but I used what I had. To fit in the included file the bearing needs to be 22mm outer diameter. Print the bushing to adapt to 5mm. 5 meters of gt2 6mm belt. short M5 bolts and t_nuts for mounting parts to 2020 extrusions Here are the links to some parts. https://www.amazon.com/dp/B07JKT5BZQ?psc=1&ref=ppx_yo2_dt_b_product_details https://www.amazon.com/dp/B07C6FL8TW?psc=1&ref=ppx_pop_dt_b_product_details https://www.amazon.com/Pulley-Synchronous-Wheel-Timing-Printer/dp/B08JTS1DRK/ref=sr_1_4?crid=3GA71TM049RUD&keywords=80t+gt2+pulley&qid=1638826981&sprefix=80t+gt2%2Cindustrial%2C149&sr=8-4 https://www.amazon.com/BIQU-Aluminum-Toothless-Timing-Printer/dp/B01H3F8LUU/ref=sr_1_3?keywords=smooth%2Bidler%2Bpulley&qid=1638827467&sr=8-3&th=1 https://www.amazon.com/3Dman-Timing-Closed-Rubber-Printer/dp/B07V6N32B1/ref=sr_1_3?keywords=200mm+timing+belt&qid=1638827657&sr=8-3 !!! Because of the orientation of the motors they need to run in opposite direction from each other! The standard creality board has a dual z driven by a single stepper as does the skr mini e3v2 and the Skr2. I assume you will have to rewire one stepper to run opposite. I have 2 z drivers and just reversed one in klipper. !!! I have it printing now and it is really smooth! With the standard motors the rotation distance is 10.15 in klipper but calibrate it yourself to double check!

With this file you will be able to print Ender 5 plus Belt Driven Z-Axis Mod with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ender 5 plus Belt Driven Z-Axis Mod.