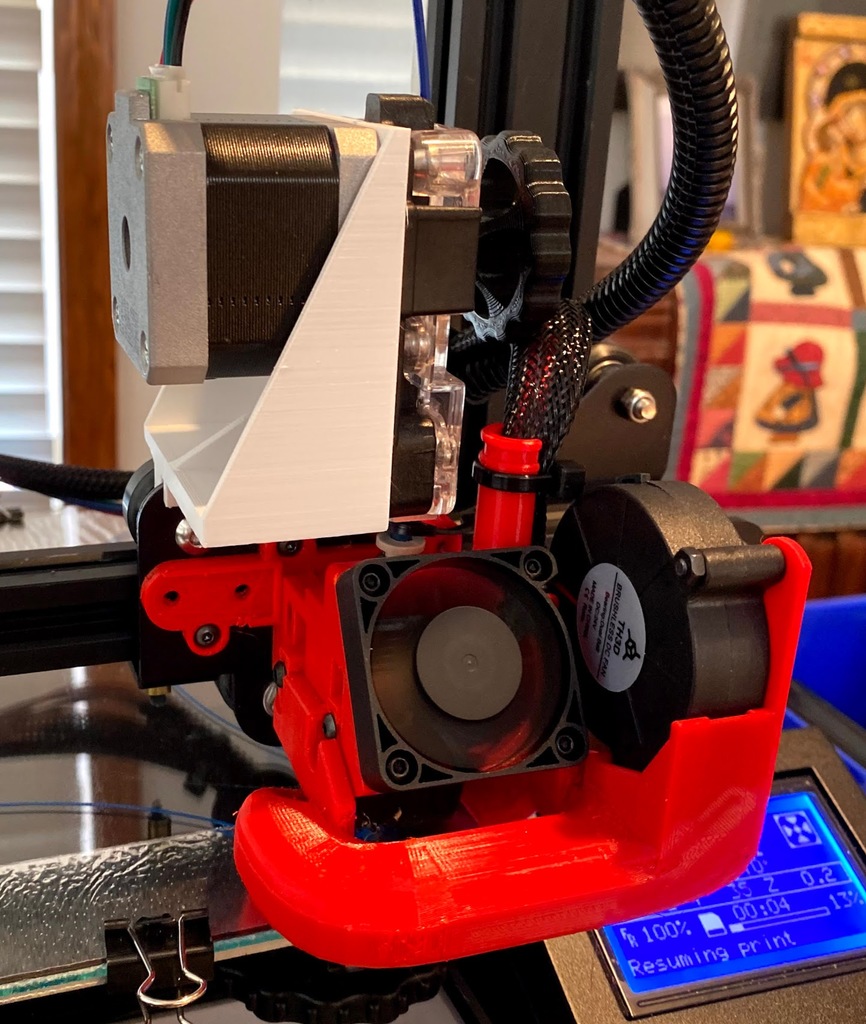

Ender-3 EZR-Struder Direct-Drive OEM-Extruder Hero-Me-Gen-5

thingiverse

It appears to be a detailed guide on how to install an EZR Struder (extruder) on a 3D printing setup. Here's a rewritten version with some formatting adjustments for better readability: **Installation Guide: EZR Struder** **Step 1: Prepare the X-Axis Plate** * Loosen the hardware for the lower roller and rotate the cam nut to release the tension on the upper two rollers. * Remove the upper two rollers, spacers, and screws. The rollers will likely be greasy. * Place the parts on a towel. **Step 2: Mount EZR Struder to Bracket** * Mount the EZR Struder through the top four bracket slots to the extruder motor. Snug down the screws but don't tighten them yet. * Use screws and locknuts that came with the EZR Struder to attach the bottom two holes in the EZR Struder and bracket. They should be snug but not tight. **Step 3: Prepare Hot End** * Remove the hot end from the X-Axis plate. * Insert the Capricorn tubing (length will be determined later) into the hot end so that it bottoms out against the nozzle. Do NOT install the fitting at the top of the hot end at this time. **Step 4: Determine Capricorn Tube Length** * Use a Sharpie to mark the length to cut the Capricorn tube so it will bottom out in the EZR Struder. * Cut the Capricorn tubing at the Sharpie mark. Make sure that you have a clean cut and the tube is not pinched. **Step 5: Mount Hot End** * With the hot end removed from the X-Axis plate, push the Capricorn tube up into the bottom of the EZR Struder. * Shift the EZR Struder in the slots to line up with the hot end, and tighten all EZR Struder mounting screws. * Insert and tighten the hot end mounting screws. **Step 6: Mount Hero Me Gen 5** * Mount the Hero Me Gen 5 ducting w/hotend but only snug down one hotend screw. * Move the EZR Struder sideways in the slots to align the EZR Struder with the hotend. * Tighten the 5 EZR Struder screws that are accessible. * Remove the Hero Me Gen 5. * Tighten the 6th EZR Struder screw. * Install the Hero Me Gen 5. **Step 7: Final Alignment and Tightening** * Move the EZR Struder sideways in the slots to align the EZR Struder with the hotend. * Tighten all screws, including the one that was previously only snugged down. Note: This is a detailed guide and some steps may require additional clarification or images for better understanding.

With this file you will be able to print Ender-3 EZR-Struder Direct-Drive OEM-Extruder Hero-Me-Gen-5 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ender-3 EZR-Struder Direct-Drive OEM-Extruder Hero-Me-Gen-5.