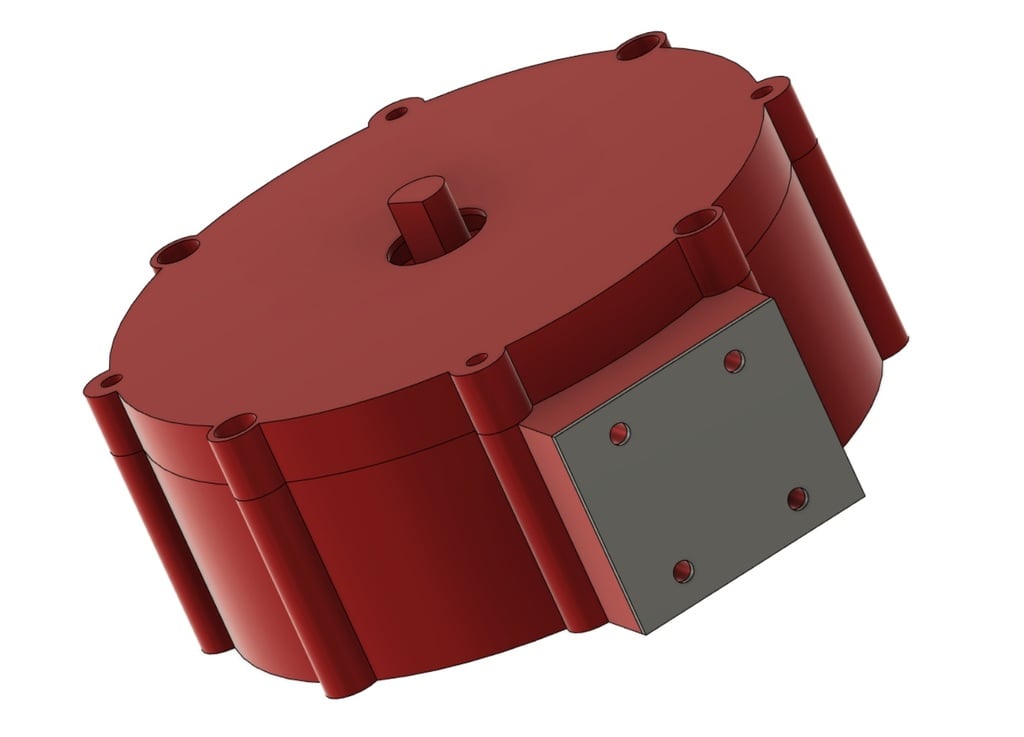

Electric Generator

thingiverse

This is a generator I built with my daughter for her 8th grade science fair. the design below will produce 12v AC. ---------------------------------- # parts list: ---------------------------------- 2x bearings - 8x22x7mm: https://www.amazon.com/gp/product/B07V3NG2XR/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1 28 gauge enameled copper wire: https://www.amazon.com/gp/product/B07DYF53ZN?th=1 32 magnets per rotor - 12 x 6 x 3mm: https://www.amazon.com/gp/product/B09L47HV7M 4x nuts - M3 4x bolts M3x12 up to M3x20 socket head screws digital counter for the coil winding tool; https://www.amazon.com/gp/product/B08VRYFXQY ---------------------------------- # 3D printing steps: ---------------------------------- all parts were printed with PLA filament using a Prusa MK3S at 0.2mm layer height i have included a coil rapping tool that you can use to make the coils ## CASE **case base.stl**: printed no supports required 0.2mm layer height **case lid.stil**: printed no supports required 0.2mm layer height ## ROTOR **roter.stl**: print without supports, 0.2mm layer height ## STATOR **stator.stl**; this is what your coils will attach to, this should print with no supports **coil.stl**; you need 8 of these, this needs supports to print the letter D should be facing the build plate. These are very delicate parts some of them may not print perfectly so make extras. To wind the coils you can use the coil winding tool (below) ## AXEL **axel.stl**; The axel needs supports to print its easiest to print standing up. it should be printed with 100% infill for strength ## COIL WINDING TOOL **coil holder right.stl**; **coil holder left.stl**; **sensor holder.stl**; attach the little magnet from the digital counter if you are using that **drill adaptor.stl**; **stand.stl**; attach the digital counter to the stand ---------------------------------- # Assembly Instructions: ---------------------------------- ## STATOR AND COIL to get 12v AC each coil requires 107 turns. The winding tool with the counter (see parts list) and a drill makes this a lot easier. Once you have made all 8 coils they need to be glued to the stator. each end of wire must be scrapped to remove enamel. solder the end of coil to beginning of adjacent coil in clockwise order. you should have 2 wires remaining from the last 2 adjacent coils. ## NUTS each of the 4 nuts goes into the slot of the case base ## ROTOR the axel will support 1 or 2 rotors each rotor requires 32 of the magnets, if you want to use less magnets you don't need to put the sideways ones in but those make the generator stronger. They create what is known as a halbach array (https://www.kjmagnetics.com/blog.asp?p=halbach-arrays). The face up magnets need to be oriental alternating north and south. The sideways magnets amplify the magnetic field so the poles should match the pole of a face up magnet. For example if the pole of a face up magnet is north and then the pole of the sideways magnets to the right or left is also north. They way to repel each other so this is how you will know they have the same pole. I recommend usinghttps://www.kjmagnetics.com/blog.asp?p=halbach-arrays glue to keep them into the rotor. Gorilla glue works well for this. ## FINAL ASSEMBLY 1. Put 1 bearing in case base and lid each 1. Put 1 rotor on bottom of axel (side without notch). magnet should be facing up towards notched part of axel 1. Fit axel into bearing of case base 1. install stator and feed wires through holes into wire box of base 1. install top rotor (if using) with magnets facing towards stator. Magnets **must** attract each other, otherwise change orientation. 1. install lid 1. attach M3 screws through lid into base and tighten

With this file you will be able to print Electric Generator with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Electric Generator.