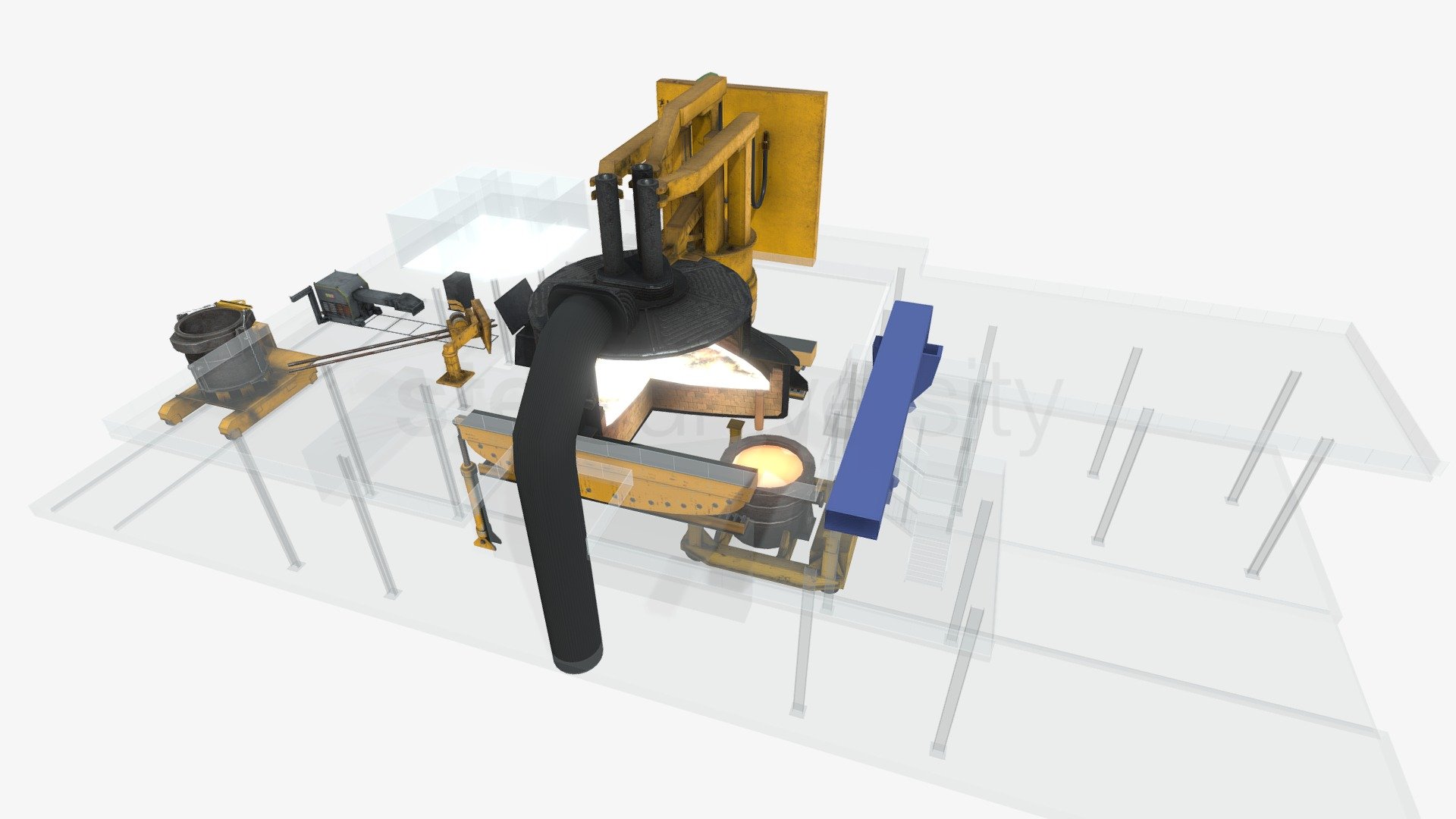

Electric Arc Furnace - Primary steelmaking

sketchfab

Electric Arc Furnaces (EAFs) are used to produce high-quality steel and carbon steels primarily by recycling ferrous scrap materials. In an EAF, scrap metal and/or manufactured iron units such as DRI, pig iron, or iron carbide are melted and converted into steel using high-power electric arcs formed between a cathode and one or three anodes. An electric current is passed through the electrodes to create a powerful arc that generates intense heat. This heat melts the scrap metal rapidly. The electricity required for this process can power a town with 100,000 residents. During the melting process, other metals called ferro-alloys are added to the steel to give it the precise chemical composition needed. Scrap metal is by far the most crucial resource used in EAFs, accounting for approximately 80% of all electric arc furnace metal feedstock. A modern EAF can produce around 150 tonnes of high-quality steel in a single melt, which takes about 90 minutes to complete.

With this file you will be able to print Electric Arc Furnace - Primary steelmaking with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Electric Arc Furnace - Primary steelmaking.