Egg Drop Challenge Lesson Plan

pinshape

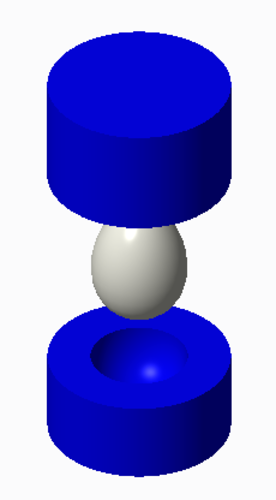

Critical thinking and design are fundamental building blocks of engineering. Modern technology such as 3D printing now offers a fresh avenue for exploring creativity and accelerating prototyping. The enclosed files represent an updated version of an educational science activity (Egg Drop Challenge) that reinforces key principles of design, material benefits, and the impact of 3D printed infill percentages with modern adaptation. The CAD model of the egg can be used to inspire innovative mechanisms or housings that enclose and protect an egg from high force or impact. Students can use the model of the egg or dimension their own egg to build a truly unique and customized enclosure, practicing fundamental design elements (dimensioning, drawing, sketching). This lesson plan aims to observe the effects of various infill percentages and how they respond when subjected to force. The two egg container components are designed to encase the egg and maintain a static position with their flat surfaces. The flat bottom surface of the containers allows the egg to be positioned on a flat surface, while the contoured cap maintains a flat top to allow for loading conditions. This demonstrative lesson will provide a visual representation of the effects of infill percentage. Not only can this process be performed for infill percentage, but the orientation of the models can also influence their loading capabilities and can be tested. To visualize the effects of various infill and measure the force response, print three different sets of containers with infill percentages of 10%, 50%, and 100%. To demonstrate the effects of orientation, print another set with an infill percentage of 10% in a direction opposite to the first set of containers. This second set of containers will demonstrate the influence of orientation. With the printed containers, apply a known force or weight incrementally to the desired container with its respective infill percentage and record the response until the egg is broken. Repeat this process for the remaining containers to see the effects of infill percentage. The visualization and experimentation can be conducted at the beginning of class to instill the characteristics of each property in the students. To incorporate design elements with CAD, have the students create custom egg enclosures for different infill percentages. Separate the students based on the previously studied infill percentages to see how the effect of infill percentage shapes design. Groups with lower infill percentages may need to create creative enclosures to provide greater support. The main design requirements are: the enclosure must have a flat top, the enclosure must have a flat bottom, and the enclosure must fit an egg. Additional design constraints can be imposed based on academic standing or age, such as volume, cost of material, print time. These elements can actually shape the design and may even dictate the infill percentages (i.e., time). These constraints can impose realistic demands much like those in industry or teach students to meet deadlines. If the instructor has access to various materials such as rubber or NinjaFlex, an additional lesson might involve designing rubber-like enclosures or caps to observe the effects of dampening characteristics. The 3D printed models can be designed to accommodate the rubber enclosures and loading can commence much like the previous test.

With this file you will be able to print Egg Drop Challenge Lesson Plan with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Egg Drop Challenge Lesson Plan.