Easy ABS Print Base

thingiverse

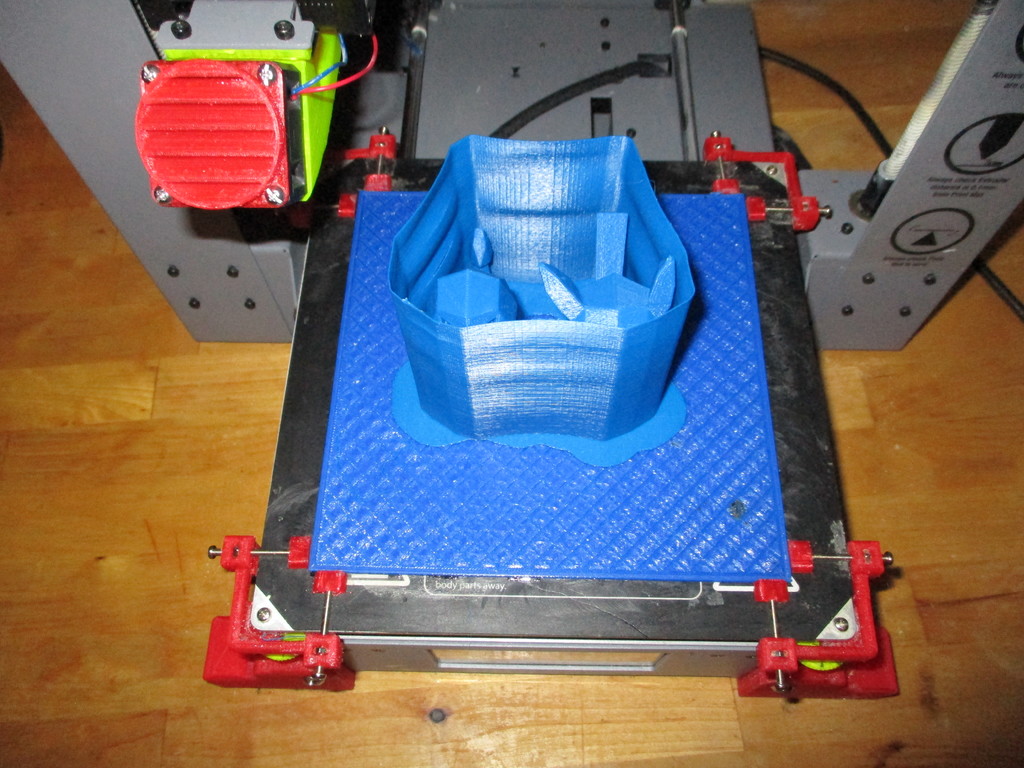

Tired of struggling with ABS prints that always seem to fail, I decided to find a solution to ensure perfect bed adhesion. Drawing inspiration from various ideas presented by Makers Muse and 3D Printing Nerd videos, I combined two concepts: using PETG as an intermediate material and creating a diamond surface through over-extrusion on the first layer. The result was a design that withstood failure and incurred minimal damage from one print to another. To create this base, you'll need a printer capable of printing PETG, double-sided tape (thin double-sided sellotape works well), and a means to prevent side drift. Notes and Warnings: - ABS prints were made at 240 degrees Celsius with a heated bed set at 90c. A raft and draft shield were used; please avoid cold printing as it will simply peel away. - The bond between ABS and PETG at 90c is incredibly strong. After experiencing a failed print due to broken filament, I learned the hard way that trying to remove the print immediately can cause warping - wait until the temperature reaches 50c before using a scraper to separate.

With this file you will be able to print Easy ABS Print Base with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Easy ABS Print Base.