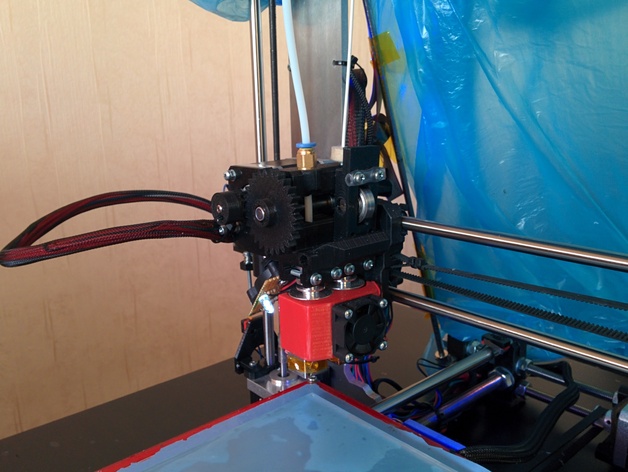

E3D i3ext dual hybrid extruder

thingiverse

This design is a modified version of my earlier i3ext release by sgraber. It employs an E3D compatible mounting rail and offers the option to use a bowden-fed second extruder. The distinctive feature is that it feeds the first extruder via a gear system, while the second extruder uses Bowden. This allows precise prints with the initial nozzle and semi-precise ones using the second nozzle, making it ideal for support material or dual-color printing with an optimized bowden setup. The tradeoff between carriage weight and accuracy is impressive. The bowden system is compatible with 1/8" standard pneufit and 4mm OD bowden tubing. The hot ends are positioned 25mm apart, the minimum distance for E3D hot ends. Two fan shroud options exist, a thin one needed if your X carriage interferes. I've personally tested this system for months and found it reliable. Here is a print made with the bowden-fed extruder: [http://www.youtube.com/watch?v=Ef02mAOPs5s](http://www.youtube.com/watch?v=Ef02mAOPs5s). The v3 extruder has a reinforced back body, cleaner fan mount holes, and space for a short PTFE tube for direct extrusion side, enhancing its performance with super flexible filaments. The bowden extruder I'm using: [http://www.thingiverse.com/thing:26817](http://www.thingiverse.com/thing:26817). For assembly instructions, follow the i3ext guidelines (see sources). Cut a bowden tube and insert it into the 4mm hole beneath the pneufit. Install the pneufit, hot ends, and fan shroud. To calibrate nozzle heights, place paper behind the upper or lower linear bearings in the carriage.

With this file you will be able to print E3D i3ext dual hybrid extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on E3D i3ext dual hybrid extruder.