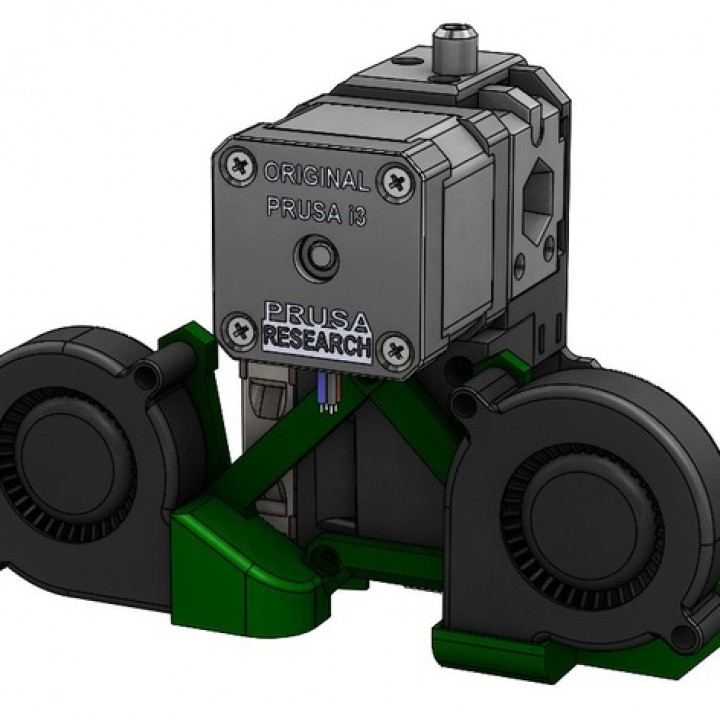

Dual Fan shroud with a view

myminifactory

A modification of the standard MK3 Fan Shroud is made to allow mounting of a second blower for extra cooling power. Additionally, it provides a clear view of the nozzle so you can watch the filament being laid down. Overhangs are drastically improved, and bridging has been tested without failure up to 280mm - as much as I could fit onto the bed. This object was created because I wasn't happy with the uneven way in which the stock shroud on the MK3 (R2 at the time) cooled parts such that overhangs only really worked when facing the front of the bed. Adding a second fan for more power seemed an easy solution, and early iterations of this design did just that - more power through the same shroud. During this process, I noticed that I could significantly improve the user experience by creating a clear view of the nozzle and heatblock. CFD is used to optimise the air pathways to ensure that the jets converge just at the spot where the plastic is being laid down for maximum cooling, without any risk of inducing a thermal runaway error. Test results show that performance of the printer is significantly improved. This won't dramatically change the quality of your prints, but it represents a bit step up in reliability for complex parts, while allowing you to print simple parts even faster. Note: The second fan does not need to be a "three wire" type - simply join the red/black wires of your new fan to the red/black wires of the existing Prusa fan and you're ready to go.

With this file you will be able to print Dual Fan shroud with a view with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dual Fan shroud with a view.