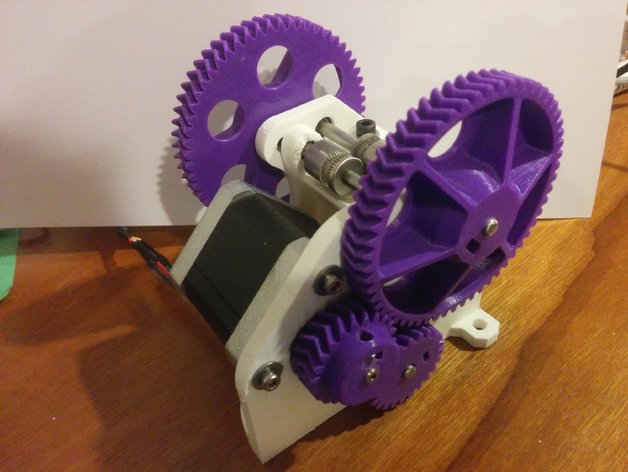

Dual Drive Bowden Extruder

thingiverse

It seems like this is a technical document on assembling a complex mechanism, specifically a 3D printer, using 3D printed parts and mechanical components. The writer provides detailed instructions on how to assemble and modify the various gears and bearings to achieve optimal performance. I'll break down the text into steps and provide explanations where necessary: ## Step 1: Preparing the Motor Gear The motor gear should be printed with 100% infill for optimal strength. A layer height of 0.2mm is recommended, but feel free to use a smaller layer height if your printer can handle it. ## Step 2: Drilling the Internal Bore Use a drill press to drill out the internal bore of each gear. The bores are usually undersized after printing and need to be enlarged using a drill bit to ensure proper meshing with other gears. ## Step 3: Concentricity Adjustment The gears must be concentric (symmetrically aligned) around their shafts. This is crucial for the gears to run true and avoid binding. You may need to use a drill press and grinding tools to achieve perfect concentricity. ## Step 4: Assembling the Gears Grub screws should not be overtightened as this can push the gears out of alignment. Leave enough clearance for the gears to mesh properly without slipping. ## Step 5: Assembly of the Pivot Arm Print the pivot arm with maximum strength and use a support material due to its complex shape. This requires careful assembly, and a slight wobble in the shaft can cause significant stress on the components. ## Step 6: Adding Washers for Centering (Optional) Washers may be necessary between the gears to maintain centering if there is any clearance or inaccuracy in their meshing. These can be slipped into place during assembly to prevent any binding. ## Step 7: Final Assembly The second large gear and idler gear at the back must be assembled as a single unit without adjustment. Due to the lack of adjustability, they must mesh perfectly together before being slid onto the shafts. ## Materials Needed For assembly: - Fasteners: M4 x 35 cap screws (2), M4 washers (4), M4 nuts (7), M4 grub screws (5) - Shafts: Three M3 shafts (80mm, 73mm, and one to length for motor shaft) for the main assembly - Gears: - Second large gear - Idler gear at back Bolts & Bearings: - Hobbed bolts with specific diameter tapped into various locations throughout the model for the stepper motor connections

With this file you will be able to print Dual Drive Bowden Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dual Drive Bowden Extruder.