Drylin Bearing Mod

thingiverse

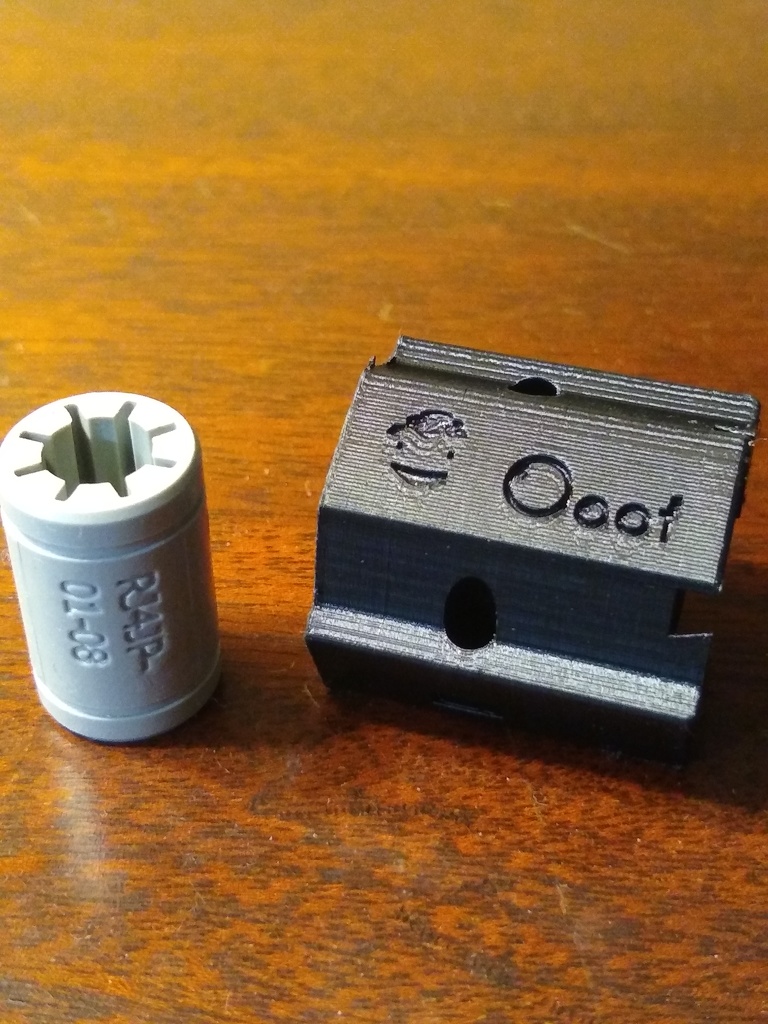

Hi everyone, I'm excited to share my experience switching from stock linear bearings to Drylin Bearings. After trying various metal sheaths to achieve the desired tolerance, none of them met my expectations in my area. So, I turned to Ruthex's design and printed a few prototypes at 100% size, then 99.5% size, and finally 99% size using PLA filament. To my delight, printing at 99% of Ruthex's design with PLA and then at 100% size with High temp PETG gave me a fantastic tolerance for the Drylin bearings. Unfortunately, the original design was too thin and prone to cracking when pressed into PETG, prompting me to create a slightly thicker bearing sheath. After two days of redesigning, I finally decided to print the new version using PLA instead of PETG. The results are amazing – the PLA is working wonderfully so far. When printing at 99% of the actual size, the fit can be too tight for comfort. To resolve this issue, I use a 1/4" socket and a vice to press the bearings back out, then carefully ream the inside of the bearing sheath with a 1/2" chisel until the desired fit is achieved. If you have any questions or need help with your own project, feel free to ask. You can find Ruthex's original design on Thingiverse at https://www.thingiverse.com/thing:3426297. Thanks for stopping by!

With this file you will be able to print Drylin Bearing Mod with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Drylin Bearing Mod.