DrillAndFile DIY Hot End

thingiverse

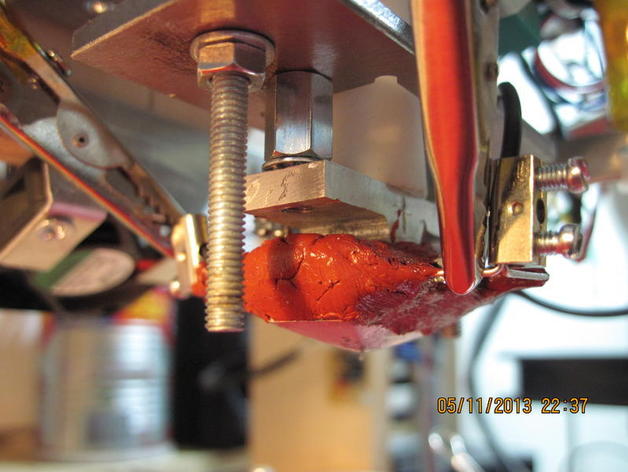

Making your own hotend is similar to baking homemade bread; you may not have access to professional tools or equipment, but nothing beats the satisfaction of creating something yourself. This DIY hotend design requires basic materials and tools without expensive machinery, inspired by popular hotends like Watson, KISS, and Wildseyed Simple Hot End. The current version is v3, which works exceptionally well for printing calibration pieces, robotics parts, and even all components of a custom Mendel90. The gallery displays examples of prints made with v2 and v3 using a 0.5mm nozzle. The key to this hotend's precision lies in its simple construction process: drill the holes first, then file it into shape. This method allows for minor drilling inaccuracies while resulting in a highly precise final product. No lathe or milling is required; only drilling, cutting, and filing are necessary. The cost of materials for a single hotend is approximately 5 EUR, but purchasing larger quantities may be needed to access specific sizes. Detailed documentation for building this hotend can be found at http://reprap.org/wiki/DrillandFile_Hot_End, and the step-by-step build process is available on the main documentation page.

With this file you will be able to print DrillAndFile DIY Hot End with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on DrillAndFile DIY Hot End.