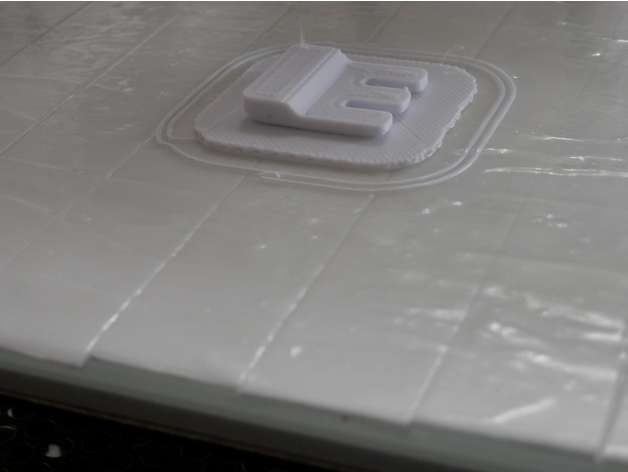

Dried PVAc Bed for PLA Printing

thingiverse

Put a double-sided tape on the glass plate and paint it with PVAc glue, letting it dry completely. This prevents warping of ABS & Nylon prints and makes printing easier. Requirements: A high-adhesive-strength double-sided tape is needed. PVAc glue must be used to create a strong bond between the print bed and the nozzle. A ruler or palette knife is required to spread and flatten PVAc glue evenly. For PLA Printing: The distance between the print bed and the nozzle should not be too close, as PLA sticks easily to the PVAc bed. This causes filaments to become stuck with the print bed and will not peel off. To avoid this issue, separate the print bed and nozzle by a suitable distance. For ABS Printing: A small 3D model is recommended for printing with ABS. Large models can cause printing failure due to warping of the material. The distance between the print bed and nozzle should also be adjusted when printing with ABS. This helps stick the first layer of raft to the print bed, making it easier to remove after printing. Heated Bed: If using a heated bed, set the temperature lower than the heatproof temperature of double-sided tape to prevent damage. Slicer Settings: Using a thick double-sided tape makes the print bed thicker, requiring manual adjustment of the height. However, adjusting the nozzle distance from the print bed on the slicer side saves time. Slic3r Settings: To adjust the nozzle distance from the print bed in Slic3r, go to Printer Settings -> General -> Size and coordinates -> Z offset. MatterSlice Settings: In MatterSlice, you can adjust the nozzle distance from the print bed by going to SETTINGS -> Printer -> Print Area -> Z offset. Continuous Printing from Skirt to Raft: MatterSlice allows continuous printing from skirt to raft. This helps print the first layer of raft perfectly and reduces the likelihood of failure. Notes: Drying Time: It takes about 1-2 days for PVAc glue to dry naturally. However, drying with a fan can speed up the process, but may cause dust accumulation. When using a heated bed, set it below the heatproof temperature of double-sided tape. Necessity of Raft: The surface of the dried PVAc layer is uneven, making it necessary to print with a raft. To increase heat resistance, use Version 2, which features waterproof sandpaper. Alternatively, stack multiple layers of PVAc glue for enhanced heat resistance.

With this file you will be able to print Dried PVAc Bed for PLA Printing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dried PVAc Bed for PLA Printing.