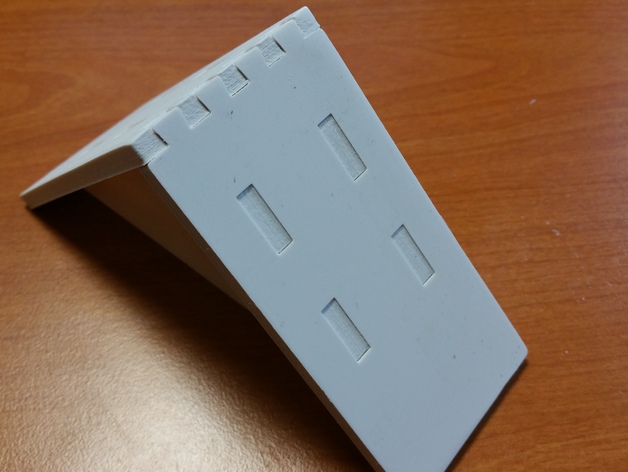

Dovetail & tenon mortise joint

thingiverse

Woodworkers worldwide have employed the mortise and tenon joint for thousands of years to connect pieces of wood at a 90° angle. At its core, this ancient technique is both straightforward and incredibly robust. While numerous variations exist, the fundamental mortise and tenon consists of two key components: the mortise hole and the tenon tongue. The tenon, cut on the end of a rail, fits snugly into a square or rectangular hole in the adjacent member. Its design ensures a precise fit, with shoulders that seat securely when the joint is fully inserted. The mortise and tenon can be secured using glue, pins, or wedges to guarantee its stability. Woodworkers rely heavily on the dovetail joint technique for various woodworking projects, including furniture making, cabinet construction, carcase building, log cabin assembly, and traditional timber framing. Distinguished by its impressive tensile strength, this joint is commonly used to connect drawer sides to the front. A series of interlocking pins cut from one board's end meet a corresponding set of tails carved into another board's end. The pins and tails exhibit a trapezoidal shape, allowing them to mesh perfectly once glued together. This results in a dovetail joint that requires no mechanical fasteners for added security.

With this file you will be able to print Dovetail & tenon mortise joint with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Dovetail & tenon mortise joint.