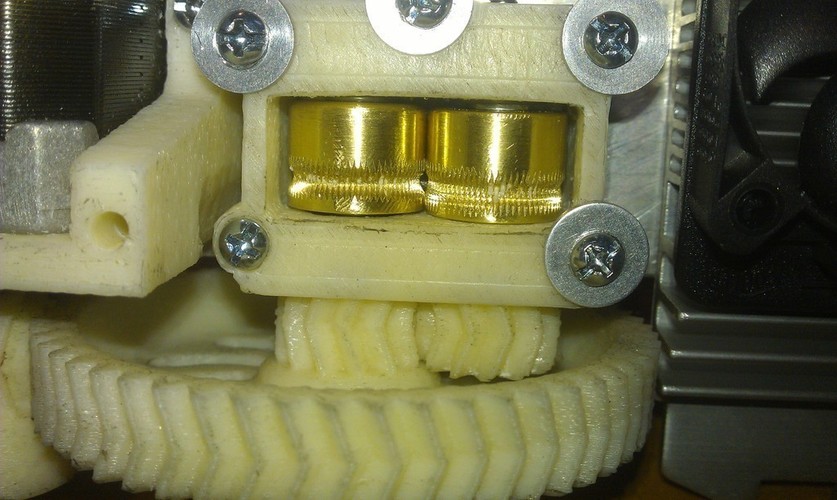

Double Barrel Extruder

pinshape

Summary This extruder design is an alternative to the "pinch wheel" type, which I found underwhelming in performance. To validate its effectiveness, I tested it thoroughly with an entire 5-pound spool of ABS without encountering any issues. The design's potential for inspiring new innovations led me to share it here, and I'm open to feedback from users who may choose to build on this concept. This project was created using Alibre and OpenSCAD, and all necessary files are included in the zip archive (Warning: File Dump). Currently, I'm focused on designing and building a next-generation printer, which will be released soon. If you have any questions or need clarification on any aspect of this design, please don't hesitate to ask. Instructions To assemble this extruder, you'll need four 624ZZ bearings, two 4mm bolts, a NEMA 17 motor, and your preferred hotend. Machining the wheels in a lathe requires some trial and error, but I managed to get it right on the second attempt. For optimal results with 1.75 mm filament, I recommend using a #10-32 tap. The entire assembly was simply secured to an aluminum plate. Unfortunately, the hobbing tool proved somewhat weak and required modification before use again.

With this file you will be able to print Double Barrel Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Double Barrel Extruder.