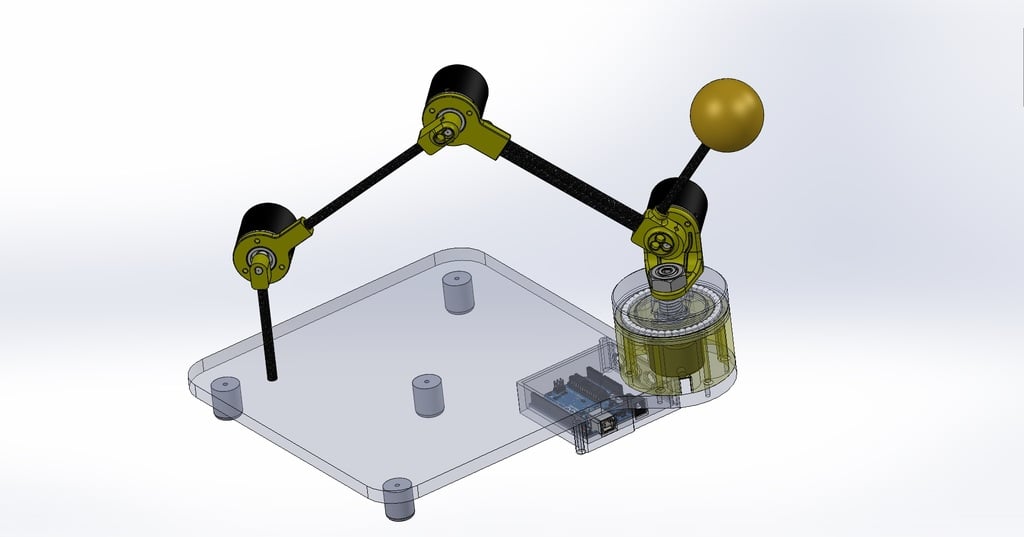

DIY CMM Arm Digitizer

thingiverse

The original DIY Digitizer project relied heavily on advanced manufacturing techniques, utilizing 3D Printing, CNC Router, and Laser cutting to bring it to life. However, this new version has been optimized to utilize only 3D Printing technology. This document includes a comprehensive Bill of Materials (BOM) file featuring links and part numbers for both standard and large-scale builds. Additionally, detailed PDF templates have been provided for drilling the base plate, which can be crafted from any flat rigid material such as PolyCARB, Carbon, or Fiberglas plates measuring 12" x 12" with a minimum thickness of 0.25". For further information, please refer to the original project at http://fablab.ruc.dk/diy-digitizer/. This document will be regularly updated as the project progresses. 05-20-2018 1. A counterbalance has been added to enhance ease of motion. 2. Two distinct Arduino enclosures have been designed, one for 3 encoders and another for 4. 3. Images of the 4-encoder assembled unit have been added. 4. The tubes forming the arm also serve as wire guides. To achieve this, the rubber sleeve is cut around the cable and slid off over the shield wire. Next, scrunch the shield over the 4-conductor wires and trim them back approximately 12 inches initially. Utilize the shield wire as a snake wire to run the cable through the tubes. If done carefully without splitting lengthwise, the shield wire can be used to reinstall the sleeve when using the 4-encoder between encoder 3 and 2, or from the base to the Arduino enclosure, as depicted in the photo. 5. All PCB connections were made on the back side of the prototyping board using PC-type pins and connectors.

With this file you will be able to print DIY CMM Arm Digitizer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on DIY CMM Arm Digitizer.