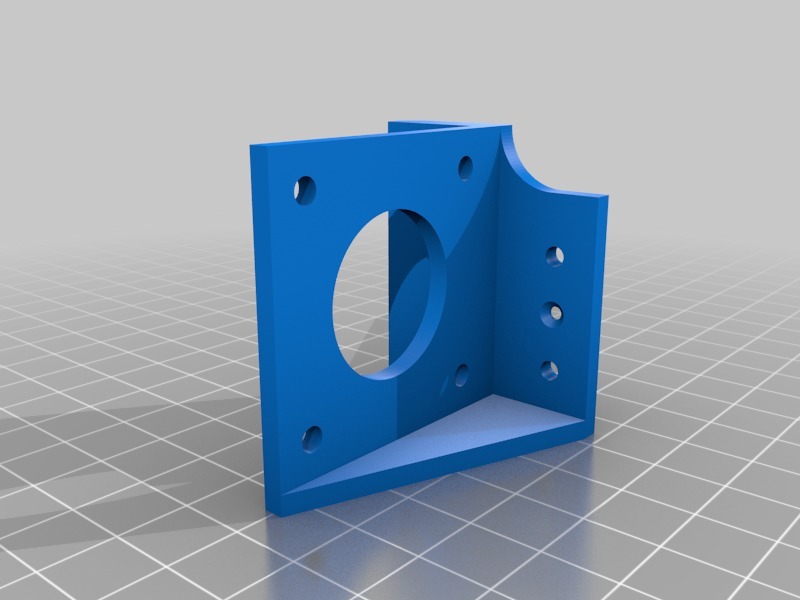

Direct drive mount for Geeetech A10 (stock parts)

thingiverse

This mount lets you ditch the bowden tube and run your printer as a direct drive. It will work with stock motors and extruders, but it's recommended that you use a metal Mk8 extruder along with a Mk8 hobbed drive gear. Direct drive offers more precise extrusion, especially at the start and end of a line, because it eliminates the slack in the bowden tube. Note that the bowden tube can hide problems with your extruder and E motor, so you'll want to use high-quality hobbed drive gears and good motor drivers or TL-smoothers. This design keeps the PTFE tube secure in the hot-end, which prevents it from pushing itself out (a common problem with bowden). This means that filament won't collect and solidify in the heat break, clogging the hot-end. Printing flexible filaments can be tricky on bowden setups, but direct drive should make it easier. One potential drawback of direct drive is that it may introduce more ringing due to the added weight on the printer head, but I haven't noticed this issue with my A10 (acceleration: 500, jerk: 10, speed: 50 mm/s). INSTRUCTIONS: 1) Cut the PTFE tube so it's about 1.5mm longer than it would be flush with the hot-end cage. 2) Screw in the mount to the top of the hot-end cage using two screws that secure the heat sink to the cage (the bottom is shaped to hold the tube in place securely). 3) Mount the motor and extruder to a vertical wall. 4) Enjoy the benefits of direct drive.

With this file you will be able to print Direct drive mount for Geeetech A10 (stock parts) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Direct drive mount for Geeetech A10 (stock parts).