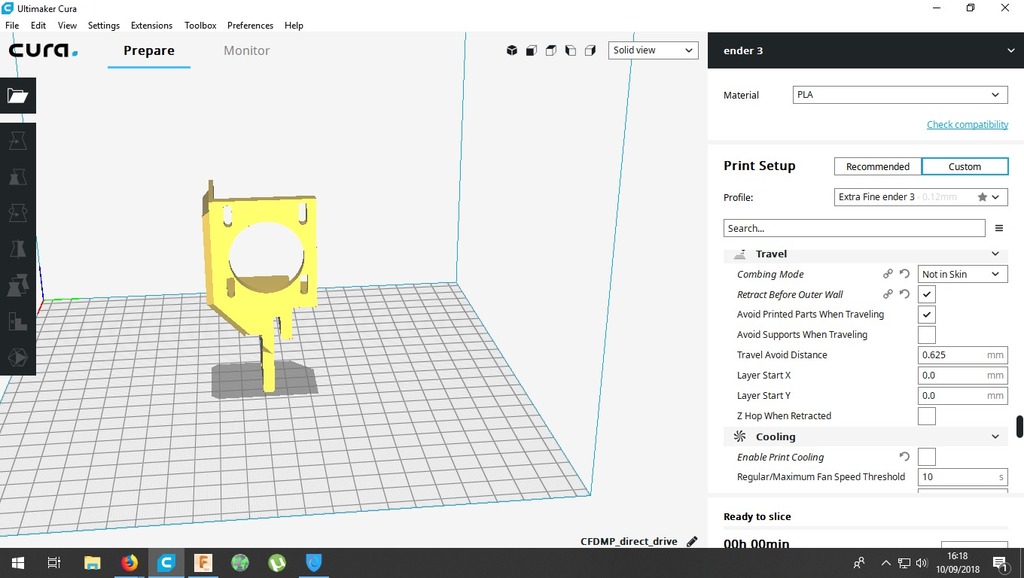

direct drive extruder mount. Ender 3

thingiverse

UPDATE 2: After several hours of using this, I've managed to optimize my retraction settings to 0.4mm retract speed 30mm/s. If you're experiencing extrusion issues, double-check that your PTFE tube length is accurate. I've just printed a revised version, which is shorter and more efficient. Additionally, I'm working on modifying the original extruder to eliminate the bowden connector and ensure full filament path support. UPDATE: The issue with couplers not aligning has been resolved. For optimal results, use the file named CE3_direct_drive_v1.1.stl. Initially, I printed the original model, but it had a major flaw - part of the design was in contact with one of the wheels on the x-axis and my pc4-m6 coupler was too long. Furthermore, the original hotend fan wouldn't fit properly. To address these issues, I modified the screw holes to slots for adjustment, accommodating the larger coupler and providing more clearance for the wheel. For a sturdy print, I recommend using 10% infill; you may want to increase this value depending on your specific needs. Don't forget that you'll need m3 screws.

With this file you will be able to print direct drive extruder mount. Ender 3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on direct drive extruder mount. Ender 3.