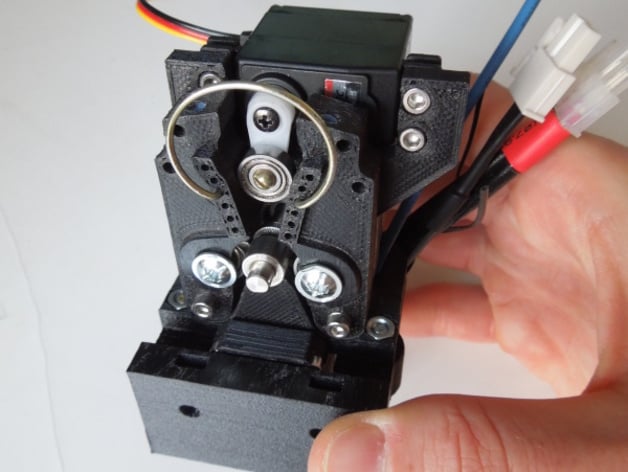

Direct drive dual extruder (single-nozzle and single-drive)

thingiverse

This is a model of a direct drive dual extruder with a single nozzle and a single stepper motor. A switching between extruders (filaments) is done by a servo mechanism that utilizes a HS-225 mini servo, as strong as bigger and heavier HS-422 servos. The model is designed for DyzEND-X hotend by Dyze Design. Here's a video of the first print. Advantages: * No filament oozing from the second nozzle. * No nozzle misalignment. * When printing from one filament on almost empty spool, it is possible to schedule switch to the new spool in the middle of the print. Disadvantages: * Wasted filament by every filament change. * Can print only with temperature compatible filaments. * Needs some retraction calibration before the first use. I just rarely use the dual printing with this extruder because DyzEND-X hotend has a big melt-zone so there is a lot of wasted filament by switching. It is worth to print just bigger parts with large layer height to minimize the wasted filament ratio. This design would benefit from a hotend with a small melt-zone. Instructions Print all the printed parts listed below and clean them by a modeler's knife, if needed. The holes for a filament can be also cleaned with a 3mm drill. 1. First, print the main body of the extruder. 2. Next, print the servo housing. 3. Then, print the nozzle holder. 4. Finally, print the temperature sensor holder. Firmware I used Marlin firmware (Release Candidate -- Marlin 1.1.0-RC7 - 31 July 2016) with the new SINGLENOZZLE feature. I modified this firmware and hardcoded the extruder switching. The definition DISABLE_INACTIVE_EXTRUDER has to be false. Toolchange scripts Use this script at your own risk! High max. feedrate value and fast extrusion (instead of retraction) might damage your extruder. G-code script for switch from filament 1 to filament 2: M203 E400 ;set maximum feedrate to 400 mm/min G4 S1 ; wait 1 s G92 E0 ; reset extruder position (set it to 0) G1 E-4 F120 ; retract 4mm G1 E-2.5 F60 ; go slowly back to 2.5mm (push slowly back 1.5mm) G1 E-39.5 F24000 ; retract fast to 39.5mm T1 ; switch to the second filament G1 E0 F1800 ; feed in the second filament M203 Exxx ;set maximum feedrate back to your default value xxx mm/min Please note that the max. feedrate defined in the firmware is in mm/s while the M203 command sets the max. feedrate in mm/min! To get the default max. feedrate value for M203 command you have to divide the value from firmware by 60. To switch from filament 2 to filament 1 just replace the command T1 with T0.

With this file you will be able to print Direct drive dual extruder (single-nozzle and single-drive) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Direct drive dual extruder (single-nozzle and single-drive).