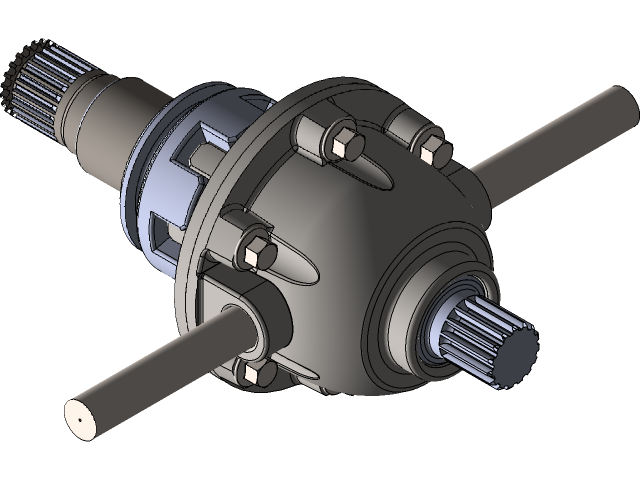

Differential Gearbox

grabcad

Designing a Differential Gearbox from Scratch using SolidWorks is an exciting project that requires attention to detail and a solid understanding of gear systems. To begin, open up SolidWorks and create a new part by clicking the "New Part" button located in the top left corner of the screen. Once you've created your new part, give it a name and click on the "OK" button. Next, draw a horizontal line to represent the ground plane using the "Line" tool. This will be the base of our gearbox. Now, draw two vertical lines on either side of the horizontal line, one inch apart from each other. These lines will serve as the mounting points for our gearbox. Now it's time to add the gear teeth. To do this, select the "Helix" tool and click on one of the vertical lines. This will create a helical gear tooth that is 1/4 inch wide and has 20 threads per inch. Click on the other vertical line to create another gear tooth. To assemble our gearbox, we need to add some shafts and bearings. To do this, select the "Revolved Boss" tool and click on one of the gear teeth. This will create a shaft that is connected to the gear tooth. Select the "Cylindrical Surface" tool and click on the other gear tooth to create a bearing. Now it's time to add some gears to our gearbox. To do this, select the "Helix" tool and click on one of the gear teeth. This will create a helical gear that is 1/4 inch wide and has 20 threads per inch. Click on the other gear tooth to create another gear. To connect the gears together, we need to add some splines. To do this, select the "Spline" tool and click on one of the gear teeth. This will create a spline that is connected to the gear tooth. Select the "Spline" tool again and click on the other gear tooth to create another spline. Now it's time to assemble our gearbox. To do this, we need to add some bolts and nuts to hold everything together. To do this, select the "Cylinder" tool and click on one of the shafts. This will create a bolt that is connected to the shaft. Select the "Nut" tool and click on the other shaft to create a nut. With our gearbox assembled, we can now add some covers to protect it from dust and debris. To do this, select the "Extruded Boss" tool and click on one of the vertical lines. This will create a cover that is connected to the gear tooth. Select the "Extruded Boss" tool again and click on the other vertical line to create another cover. And that's it! Our differential gearbox is now complete. We can use it in a variety of applications, such as in a car or truck.

With this file you will be able to print Differential Gearbox with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Differential Gearbox.