Deterministic Retraction Calibration

thingiverse

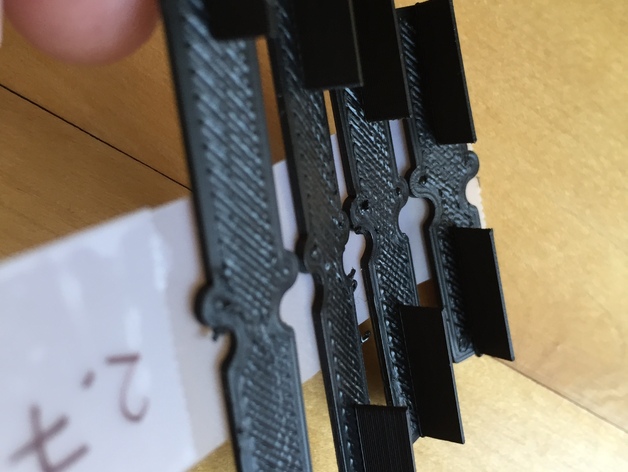

After building a brand-new printer, I realized I needed to fine-tune my retraction settings. Unfortunately, existing methods provided minimal assistance, so I found myself facing an uphill battle in creating the perfect calibration part. Each object I examined came with its own set of issues, ultimately forcing me to devise my own unique solution. To that end, I devised a comprehensive checklist of essential features for a superior retract calibration object: 1. A good retract calibration object should ideally focus solely on retraction while remaining largely independent of other calibrations. It should be straightforward to print and offer clear visual feedback, making it easy to identify any potential issues. Ideally, this object would eliminate the need for precise settings regarding cooling, overhang, Z registration, extrusion flow rate, and similar factors. In fact, relying on calibration objects that incorporate multiple variables makes them more challenging to print and harder to assess retraction performance accurately. For example, poor cooling might lead to uneven layers of molten plastic – a common misconception often attributed to subpar retraction settings rather than an actual problem with the process itself. 2. The retract calibration object should make it abundantly clear where the retraction and reload processes occur and how far the print head travels in between these events. However, numerous objects seem visually promising yet fail when subjected to detailed analysis through visualization of the GCODE path. Upon closer inspection, one often finds that extrusions don't occur exactly as expected. The travel following a retract also deviates from anticipated paths – making it rather tricky to ascertain which aspects contribute positively or negatively toward successful retraction performance under specific conditions. 3. Quantifiable results are another critical factor in assessing calibration object effectiveness. Regrettably, most existing objects offer nothing more than basic, subjective assessments of the retraction mechanism at play. Even when acknowledging some semblance of retraction success is happening, little indication remains regarding any limits or maximum performance levels such capabilities possess – leading me further away from crafting optimal prints for specific requirements. 4. Printing a retract calibration object should ideally require minimal resources and effort in terms of time, filament usage, etc., given its basic functions can accomplish this very purpose more efficiently than necessary – many objects currently being utilized far exceed minimum required quantities resulting often incomplete print jobs as well lack necessary detailed visual analysis making proper setup adjustments virtually impossible without them fully realized. Lastly, 5) It's ideal that any new design incorporates adaptability tailored towards various unique setups ensuring optimal calibration results across differing conditions allowing me customize freely as I work alongside other solutions which prove highly successful at refining my final prints accurately according accurate expectations set forth prior completion of job successfully achieved following each necessary trial successfully conducted with all previously required alterations successfully integrated within this proposed model making adjustments even simpler more accessible user experience overall. As per above mentioned design guidelines the given STL object meets my specific demands for perfecting print performance concerning calibration. With straightforward settings needed minimal extra filament is required allowing easy setup before execution allowing results obtained be highly effective without much extra investment beyond base parameters initially established – OpenSCAD source available as always so feel free modify & test any alterations freely within original provided boundaries defined above – ensuring future refinements build upon established groundwork laid previously. I used a simple rafts to hold it together Doesn't Matter My plate multiple of these on one side and print that as I like for faster print jobs - just be sure you're not having any issues related towards heating with cooling in between since there might potentially result distortion over plates after certain time spans printed before they get reabsorbed. The settings to which the prints must comply include: Plate multiple small gaps as a separate print run for smaller print objects while large print sections can simply combine and run those together if preferred. I have tried various other settings and methods, however most do not provide any consistent improvements so always remember this isn't necessary – in my experience anyway! Here are some general observations on how you should evaluate your print output during calibration: A first check that your retraction setting has an immediate effect – simply compare each printed object side by side with varying amounts set aside. This gives good starting ground when testing multiple variable possibilities and what they yield under those changed settings. I then make sure not just to analyze whether a layer looks even and clean but whether print layers come out consistently as desired every time.

With this file you will be able to print Deterministic Retraction Calibration with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Deterministic Retraction Calibration.