Designing a Parametric "Print in Place" Hinged Container Using Autodesk Fusion 360

myminifactory

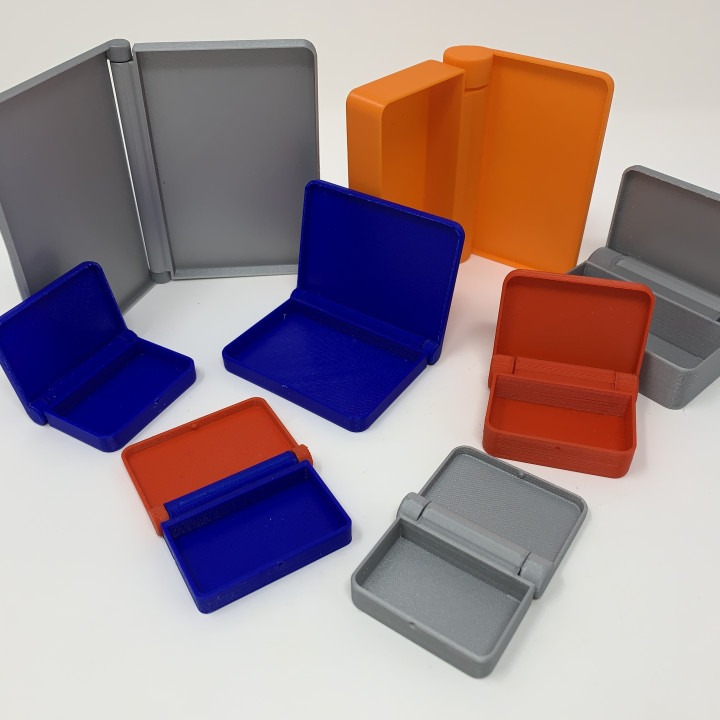

The eight differently sized and colored 3D printed "print in place" hinged containers seen in the cover photo of this tutorial all have one thing in common: they were all created from a single Autodesk Fusion 360 model using parametric modeling. In a CAD environment, a parametric model is a model whose size and/or shape can be altered simply by changing dimensional values. In this model, I specified the dimensional values for Length, Depth, Height, Thickness, and Tolerance dimensions of a simple "print in place" hinged container in the Autodesk Fusion 360 "Change Parameters" menu. I then designed sketches for the base, lid, and ball-and-socket hinges, and extruded the various components using the entered dimensional values. Thus, to change the length of the container, I simply changed the Length dimension; to change the depth, I changed the Depth dimension; and to change the height, I changed the Height dimension. When any of the dimensional values on the Change Parameters menu were altered, Autodesk Fusion 360 rebuilt the container to the new dimensions, creating a new model ready for 3D printing thanks to parametric modeling. Friends of mine questioned why I didn't simply scale the model using Cura (the slicer we use) prior to printing. The answer is that when Cura scales a model, it scales everything, including tolerances or "clearance" between parts. Thus, when scaled up, the hinge becomes loose, and when scaled down, the hinge becomes tight or even "welded." Parametric modeling ensures that user-specified Tolerance (clearance) dimensions are maintained as the model dimensions are changed. Now, the caveats: the model is not without flaws. For example, no limits have been imposed on the dimensional values, so entering "reasonable" values is up to the user. I suggest using values greater than or equal to those I initially placed in the Change Parameters menu. Negative values are a definite no-no, and excessive Height values in relation to Length and Width values will cause interesting and problematic side effects. If "non-reasonable" values are entered, errors may (or may not) appear in the timeline of the model to warn that the model with specified dimensions is not printable; so examine both base and lid components prior to printing. And as testing all possible combinations of dimensional values would require time far exceeding my remaining lifetime, I simply did not have the time to test them all. I've included the Autodesk Fusion 360 file "Print In Place Parametric Hinged Container v1.f3d" which includes the model details, and in the steps that follow are videos showing the steps I performed in creating this model (the videos may be slightly outdated, so stick with the .f3d file for updated details). Familiarity with the Autodesk Fusion 360 environment is highly recommended, and I'm always open to questions, suggestions, comments, and criticism. And that is how I created Designing a Parametric "Print in Place" Hinged Container Using Autodesk Fusion 360.

With this file you will be able to print Designing a Parametric "Print in Place" Hinged Container Using Autodesk Fusion 360 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Designing a Parametric "Print in Place" Hinged Container Using Autodesk Fusion 360.