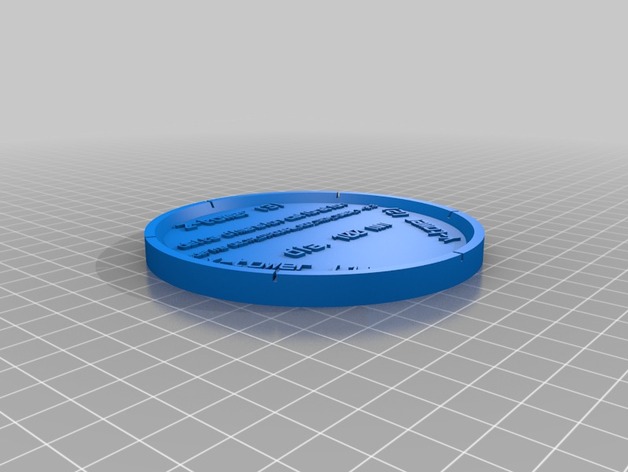

Delta printer calibration test disc

thingiverse

To calibrate your delta-style printer with Marlin, start by determining the DEFAULT_AXIS_STEPS_PER_UNIT. Print an object of known height and measure the result to find this value. Next, solve the formula x = current_steps_per_unit * expected_height / measured_height, and x will be your new DEFAULT_AXIS_STEPS_PER_UNIT. After fixing the Z axis dimensions, print this calibration tool. Measure it across in the direction of your three towers to determine how much you have to trim each tower's diagonal rod length for dimensionally correct prints. If a measurement is different from 100 mm, use the formula DELTA_DIAGONAL_ROD_TRIM_TOWER_x = DIAGONAL_ROD_LENGTH - (DIAGONAL_ROD_LENGTH * 100 / measured diameter) to correct your printer's dimensions. For example, if you measured 102 mm for tower number 1 ("X"), and your printer has a DIAGONAL_ROD_LENGTH of 255 mm, the formula would be DELTA_DIAGONAL_ROD_TRIM_TOWER_1 = 255 - (255 * 100 / 102). This will give you the amount to trim the diagonal rod length. Put this line in your Configuration.h: #define DELTA_DIAGONAL_ROD_TRIM_TOWER_1 5. This way, you can eliminate dimensional failures without measuring or modifying your printer's basic mechanical settings. Be aware that setting DELTA_DIAGONAL_ROD_TRIM_TOWER... is currently undocumented in Marlin (cf. https://github.com/MarlinFirmware/Marlin/issues/2159).

With this file you will be able to print Delta printer calibration test disc with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Delta printer calibration test disc.