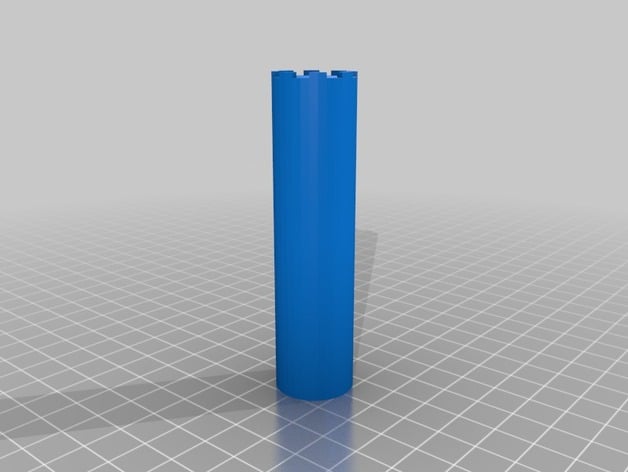

Delta Faucet Aerator Tool

thingiverse

On some new faucets, the aerator is recessed and requires a special tool for removal or installation. Such tools can be purchased under $10 if you know the model of the aerator as they come in various sizes. (A universal tool is also available.) Making one yourself can be a short, rewarding project with a 3D printer. The long cylindrical part of this tool functions like a screwdriver handle and prints without support. The long cylinder also allows the tool to be kept slightly compressed for use so that the teeth are less likely to slip out of the aerator. I didn't know what model my Delta faucets were, and I still don't. For now, I'm not concerned because this tool works on all bathroom faucets in my house. The outer diameter (OD) of this tool is approximately 21 mm. It was printed with PLA filament. While removing an aerator, I applied a significant amount of torque without damaging the tool. However, the mineral deposits on my faucets are light. On an older house with heavily encrusted aeroaters, it may take more torque to remove than this tool can provide. Print Settings Printer: ZYYX Rafts: No Supports: No Resolution: Varied according to design Infill: Varied according to design Notes: If you have an application for this tool, I recommend printing just the "test piece" first and testing it for fit. That print should take only minutes. If it fits your faucet well, then print the whole tool. If not, you can try scaling (in your slicing software) prior to printing to obtain a tool that works for you. How I Designed This Firstly, I took a photo of the aerator from under the faucet with my camera. After a few attempts (with flash and macro setting), I got a reasonably focused picture. While at the faucet, I measured the needed OD of the tool with a digital micrometer as being 21.3 mm. With the photo on my computer, I used Photoshop Elements to crop it and change the slightly oval shape my camera recorded to a circular one by scaling the image in one direction. The final result is shown below. The edited photo was imported into Blender as a background and a circle with 32 vertices placed over it where the outer part of the tool would be. I rotated the background image slightly to align with the vertices. A short test piece was generated and printed, scaled to an OD of 21.3 mm, to determine fit before extending the cylindrical part. The height of the 8 teeth was a guess that required a second test piece to get it right. Perhaps just luck, but the fit was otherwise excellent. Once the test piece fit was satisfactory, I extended the cylindrical part in Blender to function like a screwdriver handle. My total length was about 84 mm. I wanted the teeth to be printed solid for strength, but the handle could be infilled. With Simplify3D, it is possible to set up two slicing processes to print the tool, one for the lower 80 mm or so and another for the upper 4 mm portion that includes the teeth. For the lower part, I used a "fast setting": 0.3 mm layer height, 3200 mm/min default speed, and 20% infill. For the top, I used a "fine setting" with solid infill: 0.12 mm layer height, and 1800 mm/min speed. I also lowered the temperature a bit to avoid overheating the teeth while they are printed.

With this file you will be able to print Delta Faucet Aerator Tool with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Delta Faucet Aerator Tool.