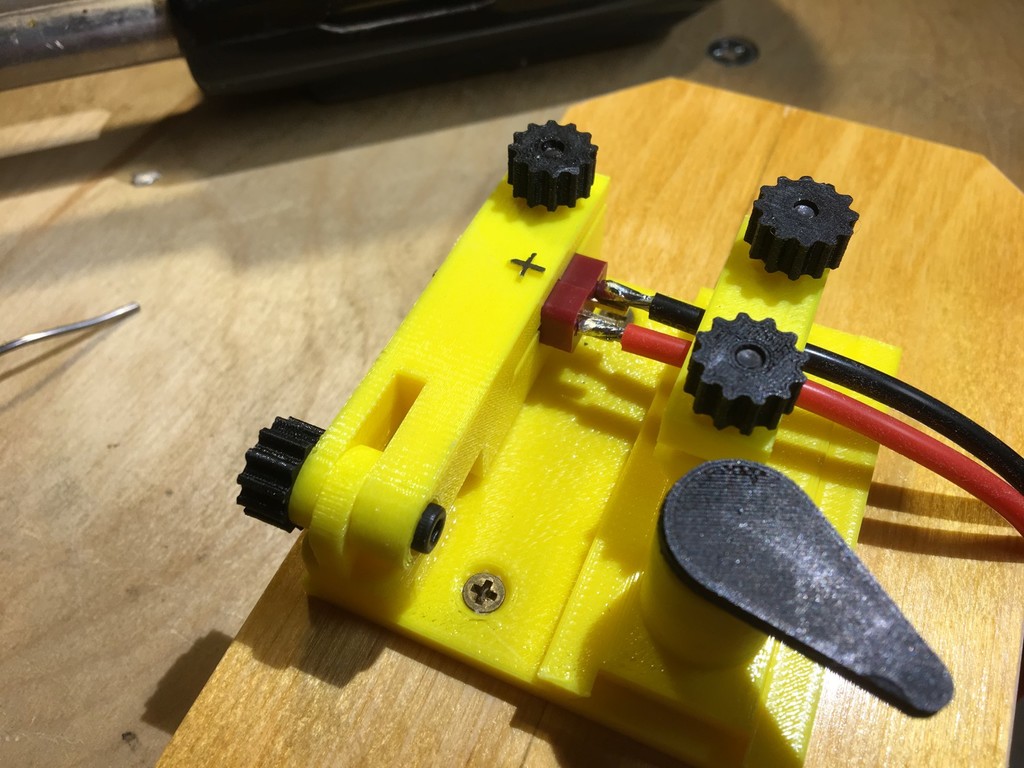

Deans Connector Soldering Helper

thingiverse

I prefer Deans connectors for my electric RC planes but they can be quite tricky to solder. To achieve a solid solder joint, you must ensure the wire is perfectly aligned with the solder lugs then get the joint hot so all of the solder melts, holding it steady while it cools. To simplify this process I built a soldering jig that holds everything just right. The plug is held by an arm which moves up and down. Two small V-grooves in the wire clamp hold the wires with precise spacing. The wire clamp can be moved horizontally and locked to align the wires perfectly. I've used the jig for soldering wire gauge 10 through 16. To steady it further, two #4 flat head screws can be screwed into a piece of board. To assemble the jig you'll need two M3X25mm and two M3X20mm cap screws along with eight M3 nuts. I usually plug the connector I'm soldering into a mating connector and clamp the mating connector in the jig. This provides more freedom to move the connector towards or away from the wires and acts as a heat sink. 9/27/18 - An additional arm design is available for slightly larger Deans Plugs.

With this file you will be able to print Deans Connector Soldering Helper with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Deans Connector Soldering Helper.