Davinci PLA Mod - featuring Repetier Host/Cura GCode tools

thingiverse

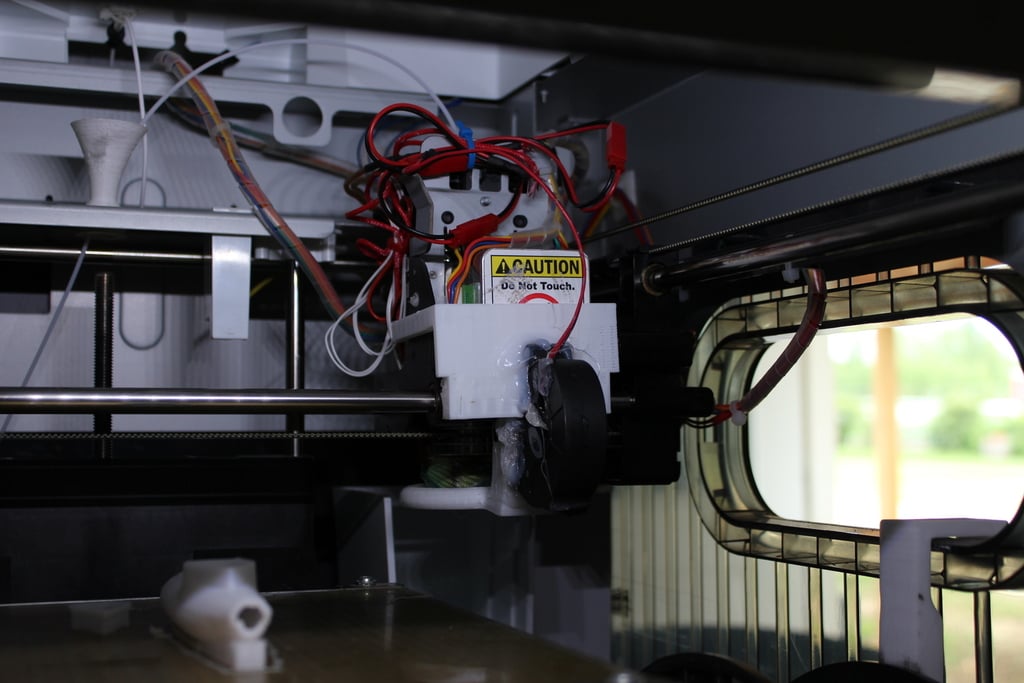

I totally forgot to set the idle time in the Davinci EEPROM settings for Repetier Host to 300000 ms, which is equivalent to 5 minutes, so make sure you add it right away. Here's a YouTube video that'll give you an idea of what kind of music can be used on a 3D printer: https://www.youtube.com/watch?v=JDYsk1KQaHk - 3D printer music! If you're looking for some G-code tools, check out this GitHub repository: https://github.com/tecan/GCODE-Tools/tree/master/GCODE-Pro. You can find a mounting bracket for your 3D printer here on Thingiverse: https://www.thingiverse.com/thing:447903. For an optical filament sensor, you might want to take a look at this thing on Thingiverse: https://www.thingiverse.com/thing:3021660. If you're having issues with your Da Vinci 3D printer's extruder thermistor, you can check out this article from Steel City Electronics: https://steelcityelectronics.com/da-vinci-3d-printer/da-vinci-extruder-thermistor/. I recently replaced the hotend on my 3D printer with a bolt-in replacement that I bought on eBay. It works great, but it does have one quirk - it only likes to be inserted and removed from the right-hand side of the carriage. The fan was tied in with an existing fan, which seemed to run fine underpowered. However, I had to cut a notch on one side of the new hotend for the first fin so that it wouldn't hit the filament wheel when inserting or removing it. I'm using a Universal Hotend 3D Printer with a MK10 nozzle and an MK8 extruder. It's been working great so far, but I did have to use other thermistor settings in Repetier Host to turn off the fan while printing PLA at 1.4 x 160 = 224. The value chart shows that this is equivalent to about 140 degrees C, which seems a bit high. However, it does seem to be working well so far. I'm hoping to get the temperature down a bit lower in order to reduce the smell of the printer. For the initial layer, I'm setting the bed at 60 and the extruder at 230, but these aren't actual temperatures because the thermistor table is off by a bit. After that, the temperature drops to 225 and 50 at z-height 2.24. I've also found that going to menu -> settings -> bed coating and setting the custom height to 22.50, then saving the EEPROM (waiting 5-10 seconds before rebooting the printer so it saves to the SD card) seems to work pretty well. However, I did have to offset the new hotend to the right because the ring would hit the heatbed if I didn't. And, of course, I had to smooth out the left side of the ring so that it wouldn't catch if it did touch. CAUTION: This hotend has a PTFE tube inside which decomposes or can melt at around 260 degrees C, releasing nasty neurotoxins in the process. So be careful not to let it get too hot! I recently had an issue with my PTFE tube where I ran out of filament and left it on only PLA temps, which caused some damage to the tube. This might be a good opportunity for some firmware mods to cut power if the printer runs out of filament (I've filed a bug report). One idea would be to get a MK10 all-metal throat/tip kit, which I'm planning to order soon. I'll also be creating new thermistor tables for various eBay parts in order to get more accurate readings. If you're looking for an upgrade to your 3D printer's hotend, you might want to check out this "MK10 All Metal Hotend Upgrade Kit" on eBay - it's only $5! However, I did have to drill out the nozzle from 0.4mm to 0.45mm in order to prevent jamming. Using a silicone boot with a wider .5 or .6 nozzle seems to help a lot with speed. Flowing at 87% for PLA works great, but I've found that 0.4mm nozzles can be a bit too jam-prone, so you might want to upsize it. I recently bought a box of micro-drill bits for $20, which includes a 0.0180 = 0.45mm drill bit and a #73 drill bit (0.609 millimeters). They have the round plastic beads on them, which make it easy to spin by finger - just rock them back and forth! Minimum extrusion is set at 5mm and retraction at 5mm, and this seems to be working pretty well so far.

With this file you will be able to print Davinci PLA Mod - featuring Repetier Host/Cura GCode tools with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Davinci PLA Mod - featuring Repetier Host/Cura GCode tools.