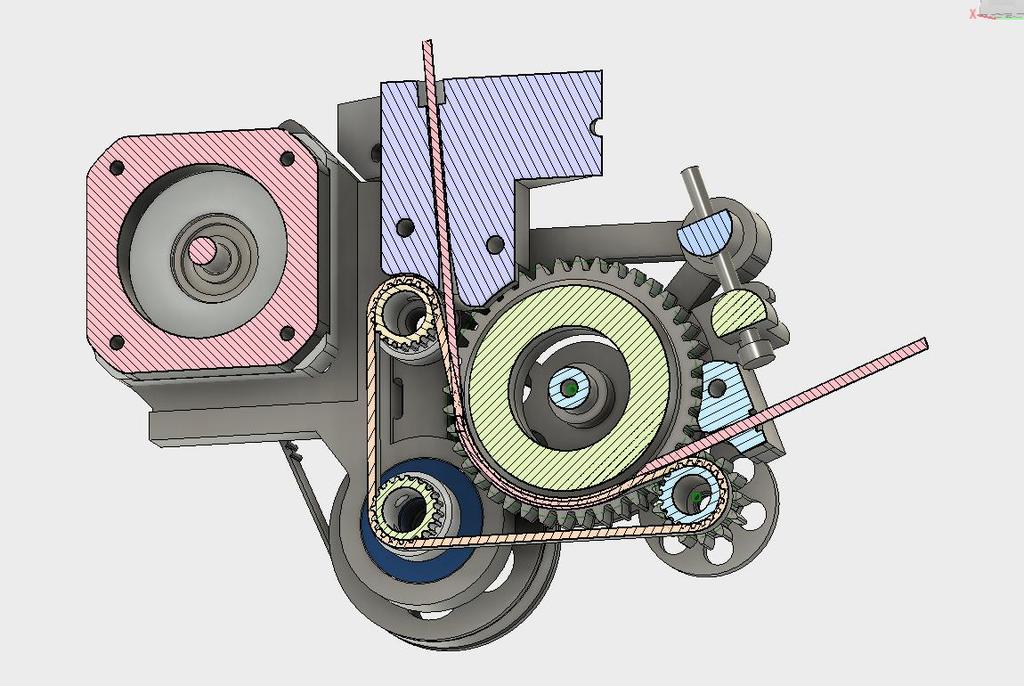

DAG Gear Belt Extruder

thingiverse

Dec 2017 I've updated everything to a version saved as "V22". \r\nYou can find step and Iges files at Grabcad (https://grabcad.com/library/dag-geared-belt-extruder-1)\r\nHere's the Bill of Materials: \r\n3mm Pneumatic fitting, M5 (for outlet)\r\nThree 3mm id 7mm od 3mm thick ball races (you'll need four, but two will do and they're cheap; it's easier to fit four than try to hold two in place)\r\n608zz ballraces (8mm id, 22mm od, 7mm thick) - three required. \r\n8mm *60mm bolt and nuts for main drive (you may also need washers to help this fit "nicely")\r\nM3 bolts : 8mm (three for holding the motor)\r\n 20mm two for the casette\r\n 30mm, three needed, two for the outlet, one to hold the casette in the main bodies.\r\n 35 to 40mm for the tensioning screw (you may be able to use a 30mm)\r\nM3 brass press in inserts (4mm dia) five needed\r\nM3 grub screws or short 8mm bolts and nuts for the Herringbone gear version.\r\nOne M3 nut for the tensioning screw (or use a brass insert)\r\nM5 30mm bolt and nut for 20T idler pulley\r\n\r\nGT2 parts:\r\n200mm belt \r\n20Tooth 8mm Drive Pulley with grub screws to hold to 8mm shaft (for main drive )\r\n20Tooth 5mm hole 9 mm thick Idler Pulley (I used a version with bearings)\r\n (or use a standard 20Tooth 5mm hole "Drive Pulley" and the alternate Motor bodyside STL) \r\n\r\nIf using the Belt drive and not the herringbone drives you will need:\r\n20T GT2 5mm hole Drive Pulley\r\n60T GT2 8mm hole Drive Pulley (or print one of you are adventurous)\r\n200mm GT2 belt (same as the main traction belt)\r\n\r\nThis design is meant for delta printers, with the outlet fitted to a 20x20 framework at the top of the printer. The outlet can be fitted first, then the main extruder "slots" onto the outlet and is held by two M3 bolts. This makes it easy to remove for adjustment/servicing. \r\n\r\nOther Notes: \r\n\r\nOct 2017 I've made slight revisions to outlets and drive gears. \r\nThe 41 tooth gear now has a slightly smaller "belt" drive diameter compared to the originally published version, reducing "slip" between the 13:41 gear ratio and the belt movement on the two parts. \r\nI've revised the outlet path to better match the actual filament path as it exits the drive, resulting in a filament path 5 degree off from the "as designed" path, allowing less lateral movement of the filament in the extruder and preventing the filament from bending under more extreme loads. \r\n\r\nhttps://youtu.be/Kta063mSm8k\r\n\r\nExperimental belt extruder\r\nDesign started as a version of the gunstruder with elements of Vaeder.\r\nThe main v drive is geared to one of the 20T GT2 pulleys, dramatically improving the drive (like the librostruder and vaeder).\r\nI've used pulleys that can be purchased easily on ebay or similar.\r\n\r\nI've tested this with my force filament sensor (https://www.thingiverse.com/thing:2429390) and in the video cut I pan to the screen displaying the force applied, showing about the same or more force than a Wade extruder before it strips the filament. The advantage of the GBE extruder is that it does not damage the filament; once the filament pressure reduces (by extruding), the filament is again driven at full force. This is in sharp contrast to a wade or similar, where once the filament strips, it can only drive at about 0.5kgf if that.\r\n\r\nI think it could be improved by changing from the belt gearing to the herringbone gearing as used in some wades, which should increase the torque on the filament further for a given motor.

With this file you will be able to print DAG Gear Belt Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on DAG Gear Belt Extruder.