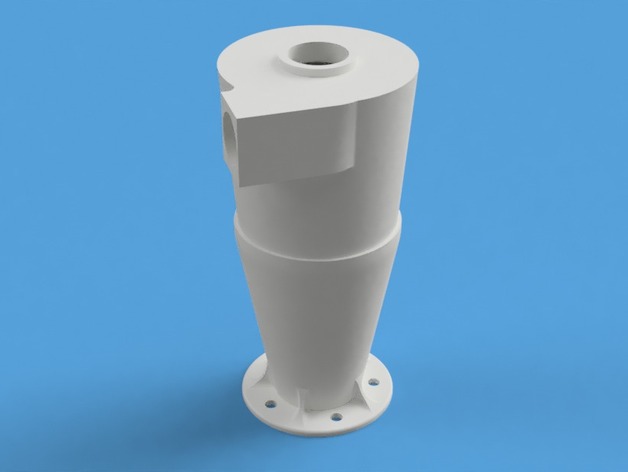

Cyclone Dust Separator

thingiverse

This is a cyclone separator specifically engineered for use in shop vac systems. I advise printing at a layer height of .3mm, accompanied by no less than three shells to ensure optimal results. Thinner layers are not recommended due to the potential for compromised structural integrity. The walls on this print may appear thicker than necessary, but the end product proves robust and durable. Post-Printing The assembly process involved gluing together various components using black ABS pipe glue. This same adhesive material is commonly employed in drainage pipes. My own supply had grown old and unusable due to its thick consistency; however, by mixing acetone into it, I managed to restore its usability. The application was generous, followed by a thorough wiping away of excess. A considerable amount of sanding on the bottom edge of the top half was required to facilitate proper fitting of the pieces together. If revising this design in the future, some clearance between parts would be beneficial to avoid similar issues. As a final step, I employed 100 grit sandpaper to knock down visible layer lines before applying Plasti Dip spray finish for both aesthetic purposes and to seal any potential gaps between layers. The base of the cyclone separator necessitates 3/8 bolts and washers. To secure it in place, I attached the unit to a standard 5-gallon bucket using a piece of 1/4 MDF as a backing plate. Design Considerations Fusion360 was utilized for the initial design stages. This particular model is optimized for use with Lulzbot Taz 5 printers; however, it may not be compatible with smaller 3D printing devices. The Fusion part file can be accessed at http://a360.co/2mt6TKt.

With this file you will be able to print Cyclone Dust Separator with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Cyclone Dust Separator.