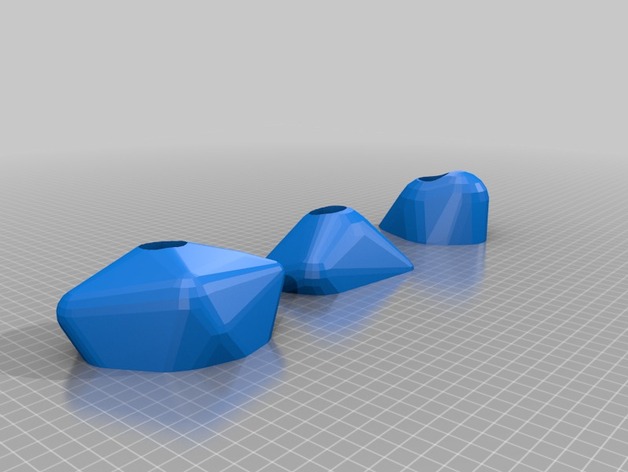

Customizable Rock Climbing Hold 2Ed.

thingiverse

This program creates an array of rock-climbing holds to be 3D printed with precision. The resulting holds are engineered to be secured with a bolt and washer into a sturdy wood-based rock-climbing wall. To ensure a secure fit, the holds feature existing countersinks. This means they can be mounted directly without needing further drilling or preparation. The size, shape, bore width, countersink width, countersink depth, and difficulty level of the holds are all adjustable. There are three output options available: Holds: These prints are designed to be printed with 100% infill, making them incredibly durable. They're perfect for rock climbers who need holds that can withstand heavy use. Molds: For a more versatile approach, you can print these molds in a flexible material like silicone. Simply fill the mold with resin, allow it to cure, and then remove the finished hold from the mold. Tray: If you prefer a multi-step process, start by printing this tray with low infill. Next, roll-pour a light coating of silicone or latex onto the tray's surface. This will create a flexible mold that can be used to cast holds. Once you've removed the holds from the tray, coat them with release agent and fill them with resin. After it cures, remove the finished hold from the mold. Follow these instructions carefully: First, this program creates an array of rock-climbing holds for 3D printing. The resulting holds are designed to be secured with a bolt and washer into a wood-based rock-climbing wall. As you'll likely need an impact driver and socket wrench to secure them, they're created already-countersunk. There are three types of output: holds, molds, and trays. Holds are designed for 3D printing at 100% infill, making them incredibly durable. The molds, on the other hand, can be printed in a flexible material like silicone (or another suitable option). Once filled with resin and cured, they can be removed to reveal your finished holds. If you choose the tray output option, start by printing it with low infill of PLA or ABS plastic. Next, pour a light coating of silicone or latex onto its surface to create a flexible mold. After filling the mold with resin, remove it from the tray and coat it with release agent before curing. Your finished holds can then be drilled and countersunk to accommodate bolts and socket wrenches. When working within OpenSCAD, you'll find a suggested filename in the console reflecting your input parameters. To capture this filename, highlight the output, right-click, and select 'Copy' from the dropdown menu. Note that Ctrl-C will not function in Windows when using this approach. Updates: June 14, 2016: The syntax was corrected to enable users to create trays and molds with precision. In addition, a rotation and translation were implemented so that selecting the tray option reveals the mold's top view. February 28, 2019: An adjustment parameter for countersink settings was added for increased customization.

With this file you will be able to print Customizable Rock Climbing Hold 2Ed. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Customizable Rock Climbing Hold 2Ed..