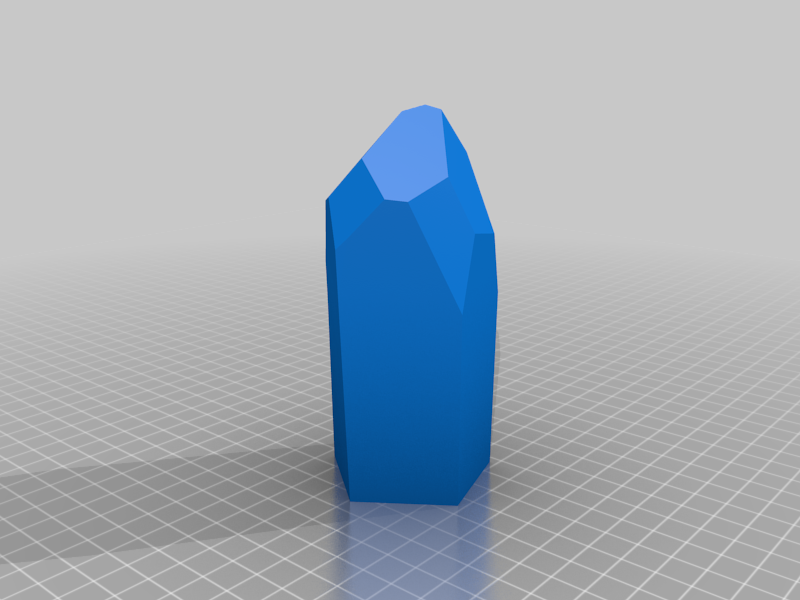

Crystal mold for epoxy

thingiverse

Can be printed right side up or upside down using a 90-degree nozzle and a bed temperature of 235C at 40mm/s travel speed. Import it into a slicer to adjust length, width, and height as needed. Pour epoxy in and let it set. To release the mold, heat it with a blowtorch and peel away the ABS. I recommend using ABS due to the risk of thermal runaway with epoxy; however, other materials can be used if precautions are taken to prevent the epoxy from getting too hot. Pouring should be done in two stages, allowing each layer to cure before adding additional layers of epoxy. The model requires wet sanding with 100-grit sandpaper to remove layer lines and customize its shape. Clean the model with a mild solvent like denatured alcohol to remove any dust; acetone will degrade the epoxy, so I do not suggest using it. Apply a final coat of epoxy using an acid or paintbrush to fill out sanding marks. I used Rust-Oleum 2-part table finishing epoxy, which has a long potting time but can be difficult to use consistently without a vacuum chamber; there are likely better products for this application.

With this file you will be able to print Crystal mold for epoxy with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Crystal mold for epoxy.