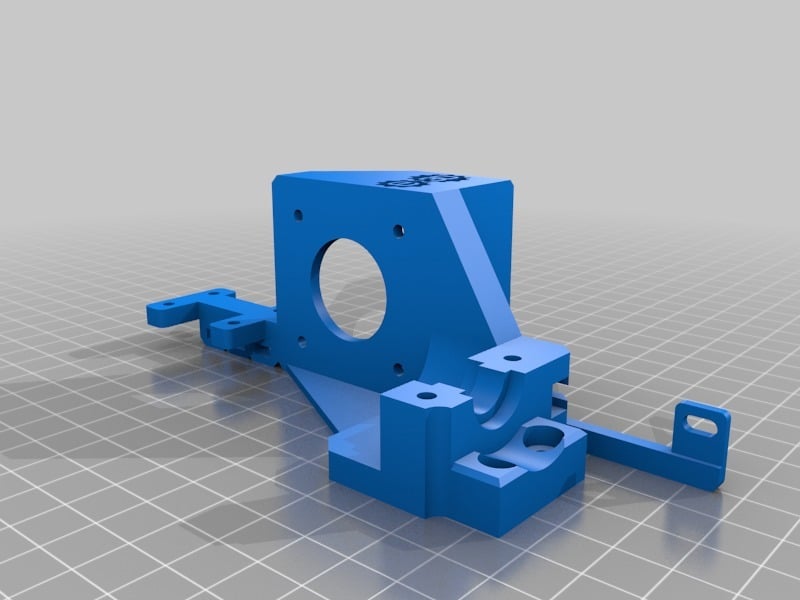

Creality CR-10S PRO E3D V6 Direct Drive Assembly

thingiverse

Human: * **Update 8/7/2019**: A revised version of **Version51_Base.stl** has been uploaded, which is identical to **Version51_Base.stl**. The model had an issue when loaded into Cura 4.2.1, so it was repaired to make slicing more reliable. The model handled correctly in Cura version 4.0.0, but users with newer Cura installations might be affected. * **Update 8/3/2019**: A revised version of **Version51_Base.stl** has been uploaded, which further improves the part cooling fan mount and widens the clap mounting holes for easier assembly. **Version35_Clamp.stl** and **Version36_Clamp.stl** also have wider holes to accommodate the clamping screws. * **Update 7/27/2019**: A revised version of **Version34_Clamp.stl** has been uploaded, which incorporates beams that span the half circle to better grip the hotend when tightened. A ring with a chamfered edge might be a better solution. **Version33_Clamp.stl** has been modified to reduce the number of triangles and improve file size. * **Update 7/25/2019**: A revised version of **Version47_Base.stl** has been uploaded, which changes the area of the part cooling fan mount. A change was made to the securing mechanism to aid in ease of positioning and a strengthened lower mount position. Be aware of electrical cables under strain. Strain is most evident with heating cartridge wires since they are stiff and not as long as other cables. * **Update 7/22/2019**: Use a more temperature-resistant build material instead of PLA, as the heat generated by the extruder motor can soften its mount. PLA is still usable but may need monitoring for signs of fatigue. * **Update 7/21/2019**: A revised version of **Version46_Base.stl** has been uploaded, which adds a feature to improve cable management. This includes adding small zip-ties and extending the wires for the stepper motor and filament sensor. The installation instructions are as follows: - Step 1: Clear the X-axis gantry and check the gantry rollers to ensure they are secure and tight enough to handle the increased weight. - Step 2: Place the heating cartridge wires and temperature sensor wires through the channel running down the back side of the assembly. Secure the base assembly to the gantry using the three indicated mounting positions. - Step 3 and 4: Attach the hotend to the extruder using shortened tubing (Step 3). Mock up the hotend-extruder assembly to the base in order to gauge when the proper distance has been met. - Step 5: Secure the extruder to the stepper motor with three indicated screws first. Fasten tightly. - Step 6: Insert the final screw and spring components to finalize the extruder assembly. - Step 7: Correct extruder gear position so that it correctly lines up with the second gear. Potential issues: Part cooling fan nozzle is too far right shifted, which might be a source of inadequate cooling. Z-axis origin based on nozzle position is shifted up from stock, and X-axis gantry might clash with Z-axis stepper motors based on your configuration. Additional modifications are required if you have modified your printer by using Z-axis stepper motor lifts in order to install a dual Z-axis synchronizing belt. The Z-axis lifts can not be used in their default state and had to be decreased in height so that the base of the Z-axis stepper motors were no more than 11-12mm above the frame of the printer.

With this file you will be able to print Creality CR-10S PRO E3D V6 Direct Drive Assembly with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Creality CR-10S PRO E3D V6 Direct Drive Assembly.