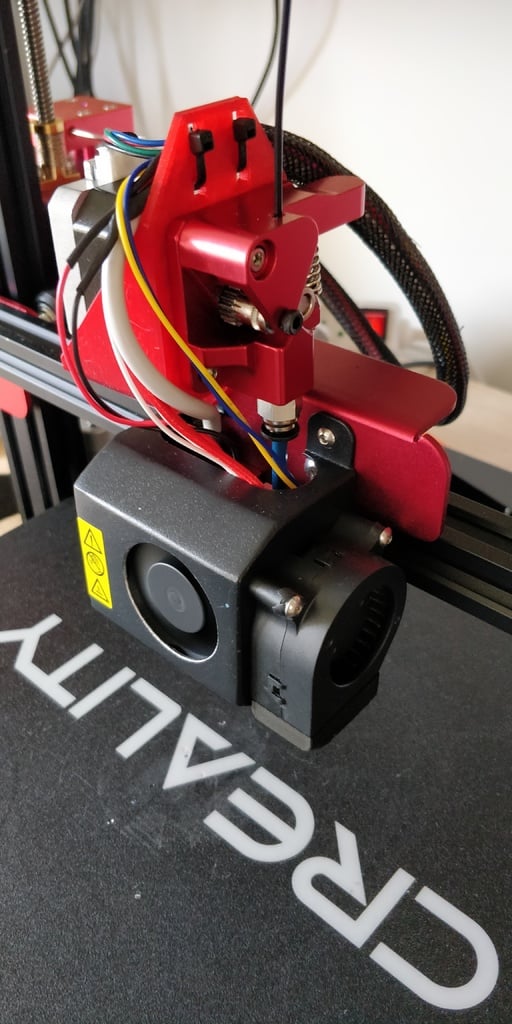

CR-10 S Pro Direct Drive

thingiverse

Here is an evolution that will change your life! I was plagued by oozing and stringing problems with my CR-10 S Pro. But after installing the MicroSwiss kit, I made the bold decision to switch from a bowden system to direct drive. This easy-to-print piece of plastic allows you to move the extrusion system directly onto the X carriage. No firmware modifications are required; your print volume remains unchanged. However, there are two potential drawbacks to consider: * The filament detector will no longer work with this setup, but I'm already thinking about a solution. * Adjusting the probe is slightly more challenging due to its inaccessible location (although it's not impossible). To make the conversion, you'll need the following parts: * A 50mm PTFE or Capricorn tube (running from the top of the MicroSwiss heatsink to the bottom of the extruder) * Two M3x10 screws * One M3 washer * One M3 Nylstop nut * A Nema 17 cable, approximately 30-40cm in length Through extensive testing with Simplify3D software, I've found that a retraction setting of 2mm at 80mm/s yields the best results. Next on my agenda is exploring ways to improve filament guidance and break detection.

With this file you will be able to print CR-10 S Pro Direct Drive with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-10 S Pro Direct Drive.