CR-10 Mod - X Belt straightener - Motor Side

thingiverse

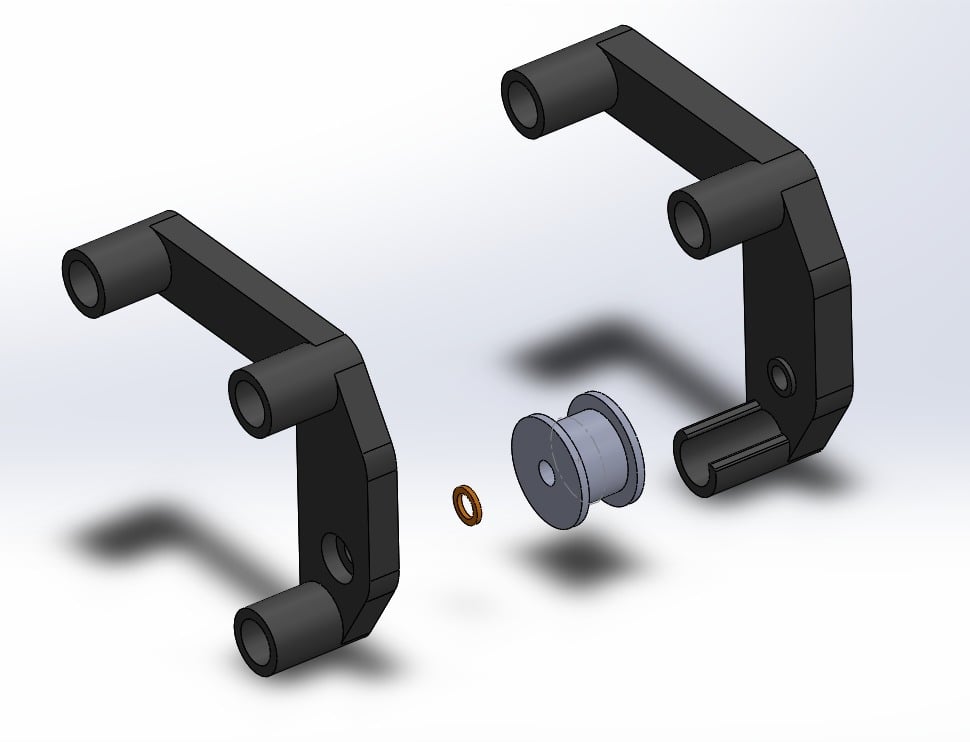

In my opinion, the CR-10 suffers from a flawed design basis for its x and y belts. All of the machine's belts are not operating in a horizontal or parallel manner to the trolleys' movement planes, but instead functioning at an angle. This angled positioning generates an error in the X-axis trolley positioning (a problem that cannot be completely fixed through e-step calibration due to the variable error along the stroke). The positioning error between 0 and 150 mm of travel is approximately 0 to 0.24 mm. From 150 to 300 mm of travel, the error increases from 0.24 to 0.28 mm (a difference of 0.04 mm due to the belts' more horizontal position in the second half of the stroke). To avoid this issue, I created a bracket with double-bearing wheels that allows the belt to operate in a horizontal position, resulting in a significant reduction in machine travel error and making x e-step calibration essentially unnecessary. No additional modifications are required for installation on the machine; only two bearings (MR105 5x10x4mm or MF105ZZ) and an M5 screw for securing the bearings are needed. Major updates have been made to match the tensioner's measurements on the other end of the X bridge. These changes include replacing the original bearings with an idler pulley GT2 16T as per the tensioner's design, which requires a single M3 screw measuring 25 mm in length. This will be the final revision for now.

With this file you will be able to print CR-10 Mod - X Belt straightener - Motor Side with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-10 Mod - X Belt straightener - Motor Side.