CR-10 Blank Dual 120mm Fan Base

thingiverse

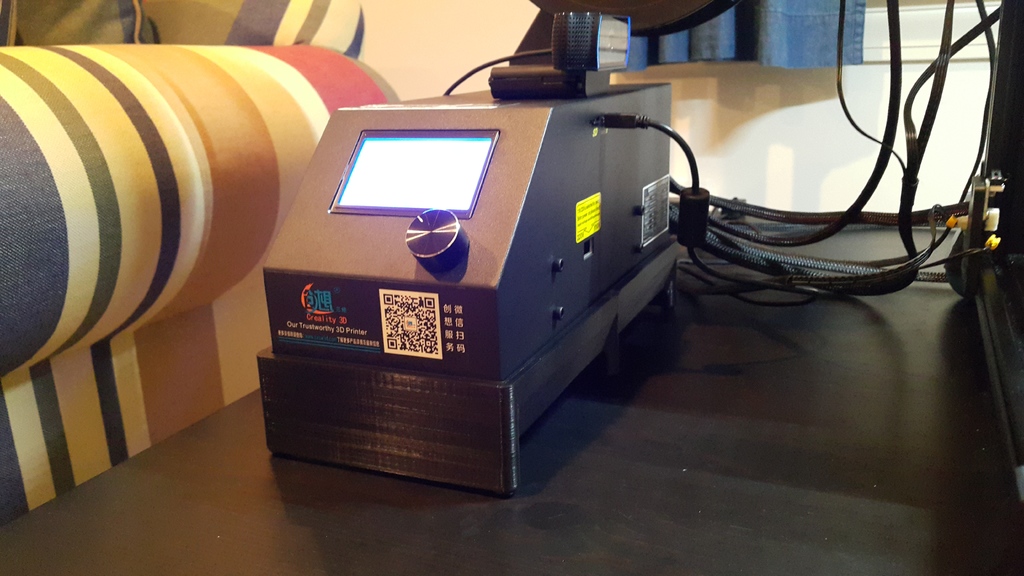

I've had my CR-10S for only two weeks, and despite loving the print quality, the noise was unbearable. Check out this video: https://www.youtube.com/watch?v=Jxmjpc5NfwM. I used the same phone to record both videos about two weeks apart. It's astonishing how dramatic the difference is. As I edited the video to upload just now, I noticed that the sound amplitude bar on the after-video was almost flat, so I uploaded a screenshot of it. I set up my printer in a bonus room upstairs on an Ikea HEMNES coffee table and while we couldn't hear the fan noise downstairs, we could hear the stepper motors as the vibrations resonated loudly in the hollow floor and drywall between the first and second floors. The first step was to install NEMA dampeners on the X and Y axis stepper motors. The second was to print and install racquetball feet. This got rid of all the vibrations, but I still didn't like how the CR-10's control box sounded like a 747 getting ready for takeoff. So, I replaced all the control box fans, which quietened it down some, but not much. That's when I printed and installed Midevil1's excellent dual 120mm fan base and used two Noctua NF-S12A 120mm fans. These are quieter and move more air than the P12 or F12 versions, making them ideally suited as a case fan. The S12's would be too loud for cooling a radiator since they have lower pressure, but they're perfect for this application. I also ordered a Noctua NA-FC1 PWM fan controller so I could turn the fan speed down a bit if needed, but it turned out to be completely unnecessary as the fans were whisper quiet at max speed. So, I removed the controller and direct wired the fans, which eliminated one potential point of failure. The only thing is that I didn't need the wire grooves or exit holes on the fan base since I was powering the fans from the internal power supply, so I filled them in and removed the CR-10 logos. I kept the control board fan as it's not very loud, but I did remove the rear exhaust fan since I aimed my fans down to pull air from the bottom of the case. My reasoning is that there are vents at the top, so I figured it would be better to pull in fresh air from there and have it blow across the main control board. Then, with the way the power supply is positioned, most of the air is drawn down into it from the rear and blows across all the power supply components before exiting. Of course, it will work fine blowing in, but I think I remember reading somewhere that pulling air from a computer case produces better cooling than blowing air in. Oh, and another thing I did to quieten it down was to replace the hot end fan with a Noctua 40x10.

With this file you will be able to print CR-10 Blank Dual 120mm Fan Base with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CR-10 Blank Dual 120mm Fan Base.