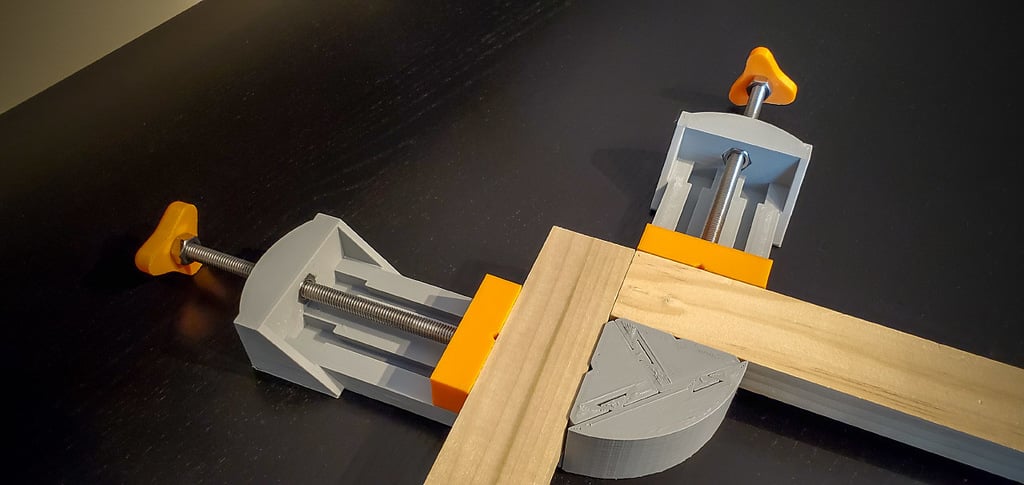

Corner Clamp Braced

thingiverse

Human: Remixing Bastien's Corner Clamp with a focus on tolerance and strength based on user feedback before printing these myself. The 109mm extended clamp has been enhanced with added braces and channels to minimize the likelihood of flexing during glue-up time. Check out Bastien's original design for additional options. This set is a subset of his design, featuring a remixed 109mm extended clamp with two variations: Base_longer_109mm Braced - A strengthened version of Bastien's clamp with original tolerances. Base_longer_109mm Braced and Tight - Similar to the above, but requires a rubber mallet for assembly; they fit snugly (the male connector's tolerance was slightly reduced). Required parts: M8 bolt rod about 120 mm long (5/16 inch, 4.5 inches long) - 2 pieces M8 hex nuts (5/16 inch) - 6 pieces Printed parts: Base_longer_109mm_Braced_* - 2 pieces Slider_V4 - 2 pieces Knob_V4 - 2 pieces Endcap_V4 - 1 piece A single Endcap_V4 is not necessary to print; it's optional for those printing only one base. Insert the M8 nuts, heat them with a solder iron to secure them in place if fits are tight. If they're loose, you can glue them, but the clamp will still function even with loose nut holders under clamping pressure. Print Settings: Rafts: No Supports: No Resolution: 0.3 mm worked well on a 0.4 mm nozzle; it's just a clamp. Infill: 40% - Rectilinear, which might be overkill, but strength is more dependent on shells; used 5 perimeters and bottom, 7 on top. Notes: Consider adding brim to prevent warping on larger parts and aid adhesion on smaller parts (handles); adjust based on your experience with filament and bed combination.

With this file you will be able to print Corner Clamp Braced with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Corner Clamp Braced.