Cord tensioner and anchor

thingiverse

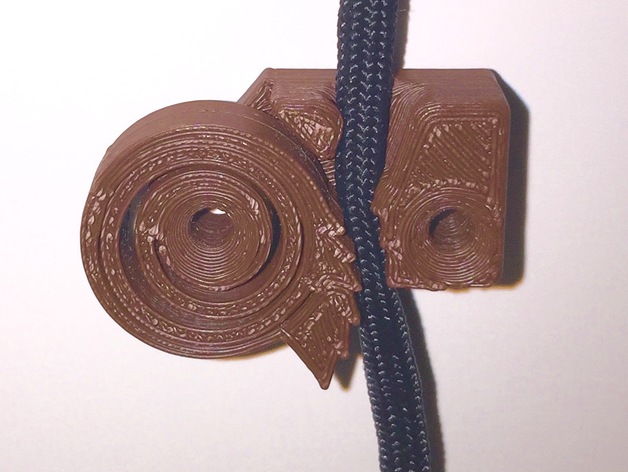

This is a 1-piece 3D-printable cam-based anchor designed for use with paracord and similar strings or cables. The spacing of the mounting holes measures 3/4 inches or 19.05mm. It is optimized to work seamlessly with #6 flat-head woodscrews. To print this model, I employ Simplify3D software, using ABS at 100% fill rate, and printing it on a raft with the beveled screw-holes facing downward against the foundation of the print. This approach prevents the spring from warping and maintains its shape, allowing for effective use of the cam mechanism. During testing, I found that if I print the spring face-down without using a raft, the lower layers tend to spread out slightly and weld together, compromising the performance of the spring's turns. Using a raft resolves this issue effectively, as it peels off fairly easily once the print has been removed. Once released from the print platform, I manually adjust the coils to free the base of the spring and confirm its full functionality. I created this design in response to several needs for securing cords or cables, particularly for a couch with an underlying storage space where a thick foam pad was situated. To prevent the foam from losing its shape when not used, I installed a cam anchor system on the bottom of the couch seat, connecting it to a corresponding point on the frame of the couch. To achieve this outcome, Autodesk Fusion 360 was employed for design purposes and NetFabb was utilized for generating mirror-image models. By creating these symmetrical versions, both left-handed and right-handed configurations could be produced simultaneously, ensuring comprehensive usability and convenience. At its core, the primary purpose of this cam-based anchor is to maintain tension in a ratchet wedge, facilitating engagement with the cord. Printing pre-tensioned springs is impossible, so the anchor alone cannot grasp or retain the cord. To achieve the perfect spring gap width, I carried out experimentation to find the optimal value for holding force transfer between the hub and ratchet. A very wide gap may compromise performance, as it doesn't collapse sufficiently for efficient tensioning of the cord. Conversely, too thin a gap risks not providing enough clearance for thick strings or cables to fit within. Recent enhancements have included incorporating ratchet teeth into the stationary block, which enables functionality with thinner, softer cords previously unable to hold. In one iteration, I also tried using a thinner backing piece, only to discover that for this application on my couch, its presence actually created tension by pushing against the upholstery in a way that let strings slip through. One feature integrated within the design includes a top slot protecting against excessive lateral movement of the cord, which can push against the spring hub and disrupt its effectiveness. When it is time to remove a string or insert a new one, merely pulling on the string to the side releases its hold, making the process straightforward and effortless.

With this file you will be able to print Cord tensioner and anchor with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Cord tensioner and anchor.