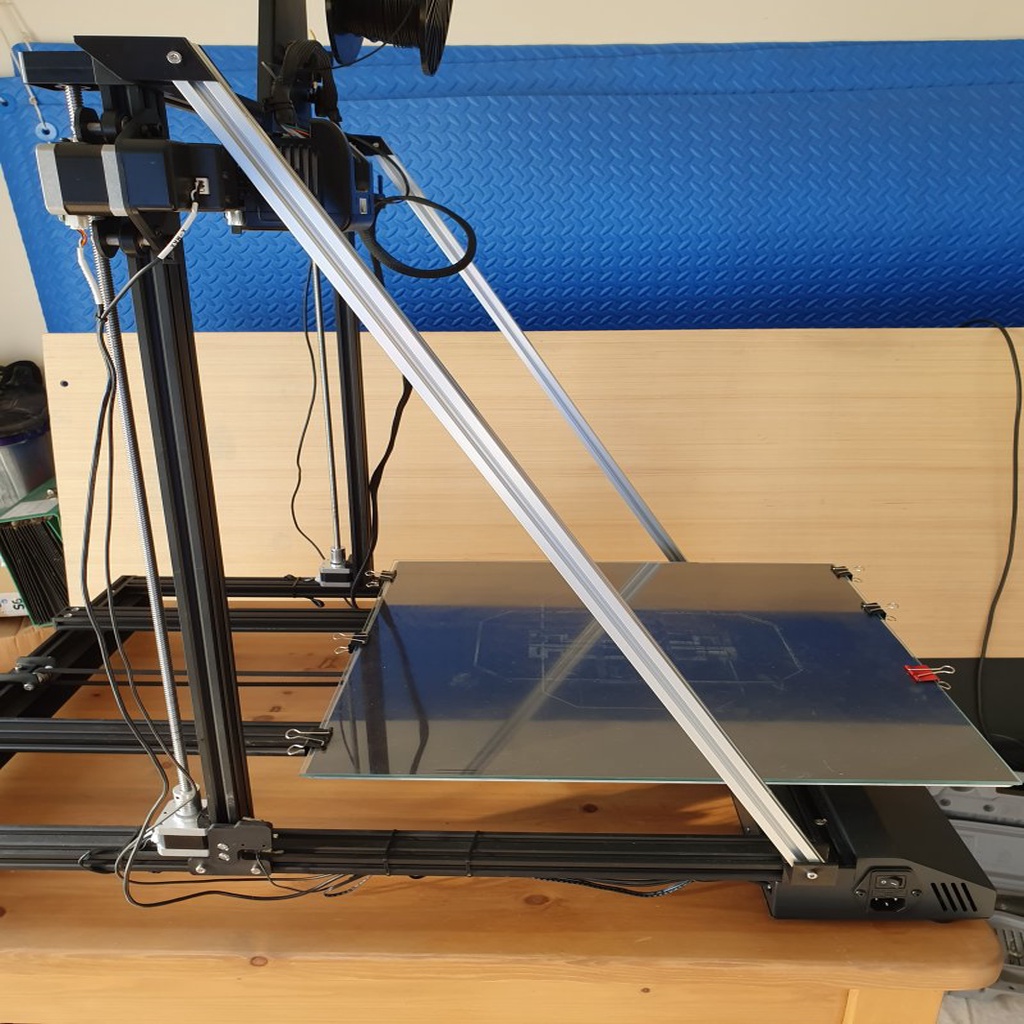

Copymaster 3D 500 brace bars

thingiverse

Human: Prepare bars for the Copymaster 3D 500. Bars are positioned outboard to avoid interference with the Z axis. Other parts required: 2 lengths of 2020 aluminum extrusion, each 800mm long. 18 M4 x 8mm socket cap screws. 18 M4 T nuts. The bars are at a 30-degree angle from vertical, so cut the ends at 30 degrees. I'm impressed with this printer due to its build volume and direct drive extruder. However, here are some helpful tips for Copymaster 3D 500 users: For better surface finish when using PLA, modify the fan shroud on the printer head to prevent air from blowing onto the part being printed. Simply removing it won't work because the same fan cools the extruder. I use a glass bed with 3DLAC, and due to the limited coverage of the bed heater, I set my bed temperature higher than usual - 50 degrees seems to work well for PLA so far. To avoid issues with filament detection, I don't route the filament through the sensor. Instead, I insert an offcut of filament into it to trick the controller. My plan is to mount the spool holder higher, allowing me to use the detector. I prefer using Simplify3D over the supplied software. My start script (adjusted for heavy bed movement and glass bed usage): G28 ; home all axes M205 X10 Y10 ; reduce jerk settings G1 Z5 F3000 ; lift the print head G1 X20 Y2 F1500 ; avoid binder clips G1 Z0.2 F3000 ; prepare for priming G92 E0 ; reset extrusion distance G1 X120 E10 F600 ; prime the nozzle G1 X150 F5000 ; quick wipe My end script: G28 X0 ; home the x-axis G1 Y450 F1500 ; move the bed to the front M106 S0 ; turn off the cooling fan M104 S0 ; turn off the extruder M140 S0 ; turn off the bed heater M84 ; disable motors Edit: I've included my fff file in case it helps anyone. So far, I'm pleased with the results using these settings and the modified brace bars. If your printer randomly shuts down, it may be due to a loose connection between the power supply cable and the controller circuit board. In my case, it was under warranty, but I simply soldered the wires directly to the socket pins after cutting away some of the shrouding. Edit2: I've added separate STL files for left and right top brace bars (untested). Edit3: I've also included a filament clip for the 2020 section, allowing you to detach the filament from the spool and position it near the extruder for easy swapping.

With this file you will be able to print Copymaster 3D 500 brace bars with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Copymaster 3D 500 brace bars.