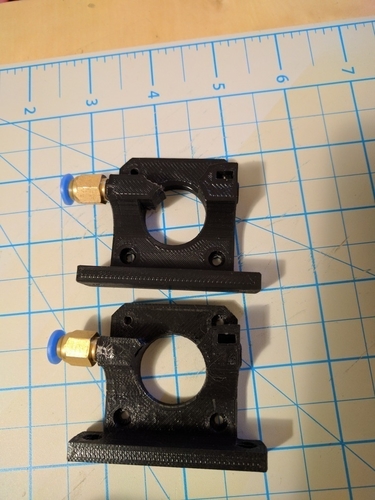

Compact Bowden Extruder for MK7 Drive Gear (1.75mm)

pinshape

All credit goes to tech2c. I undertook this project because I was consistently under-extruding. Different filaments yielded distinct results when calibrating my E steps. Upon closer inspection, I discovered a noticeable gap between the MK7 drive gear and its mount. Further research revealed that this space should be significantly reduced. Moreover, minimizing this gap would also benefit printing with flexible materials. I decided to extend the mount closer to the drive gear. As a result, my extrusion is now spot on. In retrospect, I suspect that filament may have bent previously. **Please note that this was my specific situation and might not apply to others. If you're facing similar issues, refer to the original source for more information.** Print Settings: Printer: Hictop Prusa i3 Rafts: No Supports: No Resolution: 0.12 mm Infill: 50% Notes: I printed at 0.12 mm resolution and 3 perimeters for a strong part. You can, of course, experiment with larger layer heights and reduced infill percentages. Post-Printing: Use a razor or file to ensure the filament path is smooth and unobstructed.

With this file you will be able to print Compact Bowden Extruder for MK7 Drive Gear (1.75mm) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Compact Bowden Extruder for MK7 Drive Gear (1.75mm).