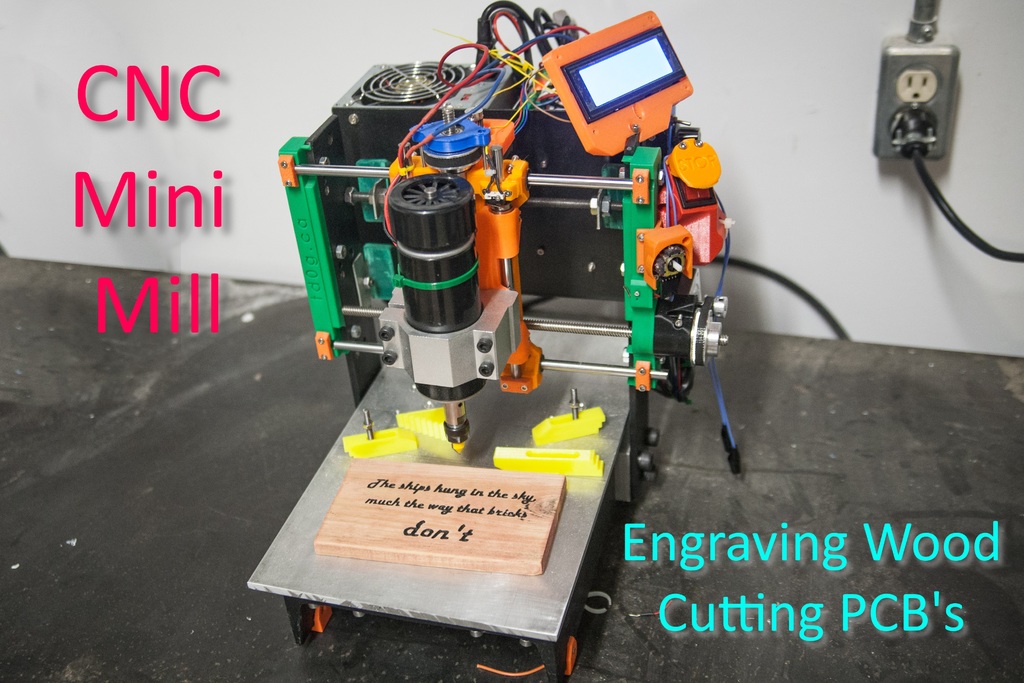

CNC Mini Mill

thingiverse

https://youtu.be/NtYTFKS2eq0 I wanted to build a mill for cutting small pieces of wood and PCBs. There are other well-documented DIY CNC mills on the internet, but I enjoy creating new things. What sets this mill apart is that it's mostly 3D printed, with all parts fitting on a 200mm x 200mm bed. This mill has worked well for engraving wood with great success. I've also started using it to mill PCBs. The results are clean enough for through-hole components, but need post-processing. This could be due to poor Eagle/PCB code settings, which I'm beginning to experiment with. For more information and assembly instructions, please visit http://www.td0g.ca/projects/cnc_mini_mill This is the initial release. I'll update the components over time. Note that some parts have odd, useless features that will be changed or removed in future versions. - Tyler INSTRUCTIONS: Each part name ending in X## must be printed ## times - otherwise each part is printed once. Don't print supports! All of the components are designed to print without them. I recommend printing the spindle mount and all motor mounts from PETG for heat resistance. The rest can be printed with PLA if you prefer. The X-gantry, X-acmeNut, Z-spindleMount, and all bearing and rail clamps require small layer heights and thick walls for strength. The remaining components can be printed with 0.8mm walls and 0.2mm layers without problem (although decreasing layer height typically improves part quality). CHANGELOG: 2019-04-17 1.0 Initial Release TODO: Remove bearing mount from front Y-rail mount (aesthetics) Add nut slots on all rail mounts (to increase strength)

With this file you will be able to print CNC Mini Mill with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CNC Mini Mill.