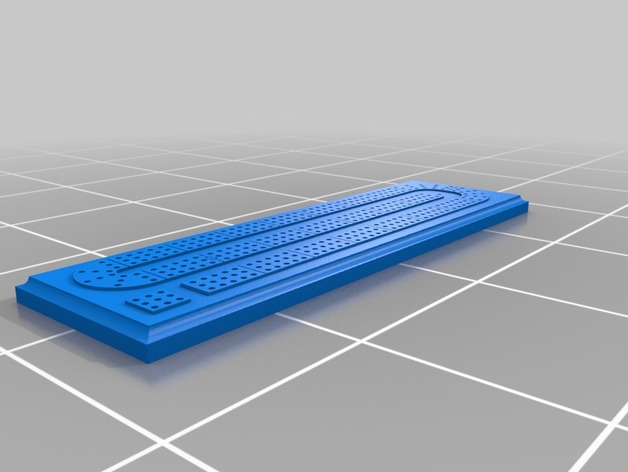

CNC Aluminum Cribbage Board

thingiverse

Here is a CNC-machined crib board design that I created several years ago. The finished length is 13.25", width is 4", height is 0.625". I made mine out of a 14" x 4" x 0.75" piece of 6061-T6 aluminum bar stock, machining was done top-down in one single setup. You will need the following machine tools: A suitable end mill to square off the ends and set the overall 13.25" length. A face mill or fly cutter to level and clean up the top surface. A 3/8" (or smaller) flat nose end mill to cut around the raised track. A 1/8" drill for the holes. A 45 degree chamfer bit to finish the holes A 1/32" end mill for the track slots and skunk marker. A 3/8" diameter ball end mill for the inverse fillet around edge of board. Optional but recommended is using a 45 degree chamfer on the hole edges, using your CAM software you can add countersinking to the STL file yourself. Use a 1/64" drill bit. If you're operating a CNC machining center and using CAM software, then you know what you're doing. For pegs, I recommend using Lee Valley part numbers 41K05.01 (brass) 41K05.02 (black) and 41K05.03 (nickel). Metal pegs are highly recommended because extracting broken wooden or plastic pegs out of the board is guaranteed to be a real pain. You'll also want a half dozen adhesive rubber feet to stick to the bottom surface of the board when it's done, to keep it in place and prevent it from marking up whatever you lay it on. I'm using Lee Valley part # 00S20.08.

With this file you will be able to print CNC Aluminum Cribbage Board with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on CNC Aluminum Cribbage Board.