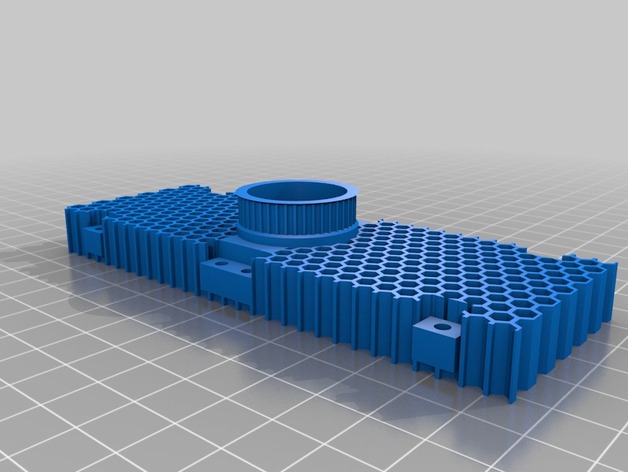

Clip-together Coroplast Wheel Parts

thingiverse

Parts for my Hackaday Prize entry:http://hackaday.io/project/2517-Entropy-Wheel-Heat-Recovery-Ventilator\nThese parts enable seamless assembly without relying on expensive specialty adhesives and will likely save a significant amount of mess. However, they do require a VERY long time to print due to the substantial material usage.\nPulley borrowed from http://www.thingiverse.com/thing:398999. Instructions Assemble these parts carefully, as they have a tendency to warp in ABS. To achieve maximum strength, print them with 100% infill. The assembly will hold a 16" long x10" diameter cylinder of coroplast sheets, roughly two full 4x8 ft x 4mm thick sheets. ABS Glue - ABS + Acetone has proven effective for preventing warping when painting over blue painter's tape. Alternatively, Kapton is an even better option, although it adheres too strongly and can be challenging to replace. The process of applying ABS glue may work well as an anti-warping measure but poses significant difficulties during removal. The honeycombs serve a critical purpose in accommodating the thickness of sheet-holding clips to prevent air leaks between the hot and cold side of the thermal wheel. For comprehensive information, reference my Hackaday.io project to understand the details on coroplast cutting. Additional tools for cutting 16" cross-grain strips are currently under development. To complete a full cylinder assembly, you need a Honeycomb Bearing Hub for the passive end and a Honeycomb Bearing Pulley Hub for the driven end. Additionally, you will require a total of 4x HE_Clip_Single_Rank_HC3, 4x HC4 parts, 4x Honeycomb_HC3, and 4x Honeycomb_HC4 pieces. You also need four honeycomb HC2 components. For cutting coroplast sheets, acquire two 4x8ft x 4mm Coroplast corrugated plastic from Home Depot (available online), with a minimum order of ten sheets at $11 each. Note that the design for the heat exchanger remains unfinished and untested, so it's recommended not to rush into production. However, the honeycomb functions could be useful in various future projects if designed with walls thick enough to withstand slicer deletions. To assemble these parts properly, ensure you press skate bearings into their corresponding sockets at each end of the hub bearings assembly. A complementary frame is under development.

With this file you will be able to print Clip-together Coroplast Wheel Parts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Clip-together Coroplast Wheel Parts.