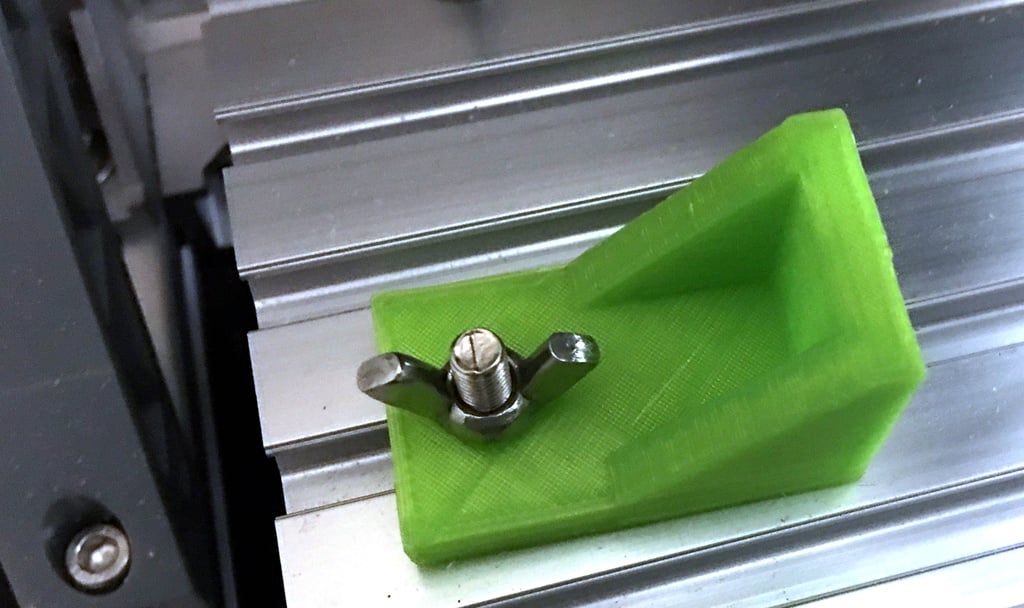

Clamp for CNC 1610

thingiverse

I purchased a budget-friendly 1610 engraver (the LinkSprite), but to be honest, I think they're all identical. It came with wing nuts for clamps, yet getting items to stay steady on the bed was a challenge. Print four of these and use the wing nuts to secure them to the bed. Unlike some models, there's no T track because the T-head bolt comes from underneath. A washer is also included, but I couldn't decide whether it should be placed on top or bottom of the part. For optimal results, aim for at least 25% infill and don't worry too much about layer height. No support is needed. Although the bases fit snugly into the bed, the jaws don't grip well. You might need to experiment with adding material to the jaws or printing with a harder plastic than PLA. The wide base provides good clearance for the wing nuts but takes up valuable bed space. It's probably clear, but you can rotate these 90 degrees as you secure them. This allows you to use one on each side of the workpiece. These would likely perform better if they were stops on one side and somehow spring-loaded on the other. I created the original design in Tinkercad, but I revised it in OpenSCAD so you can adjust it to suit your needs using the customizer.

With this file you will be able to print Clamp for CNC 1610 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Clamp for CNC 1610.