Cheap & simple Filament Guiding Upgrade for Titan Extruder & Clones - enables flexible Filament

thingiverse

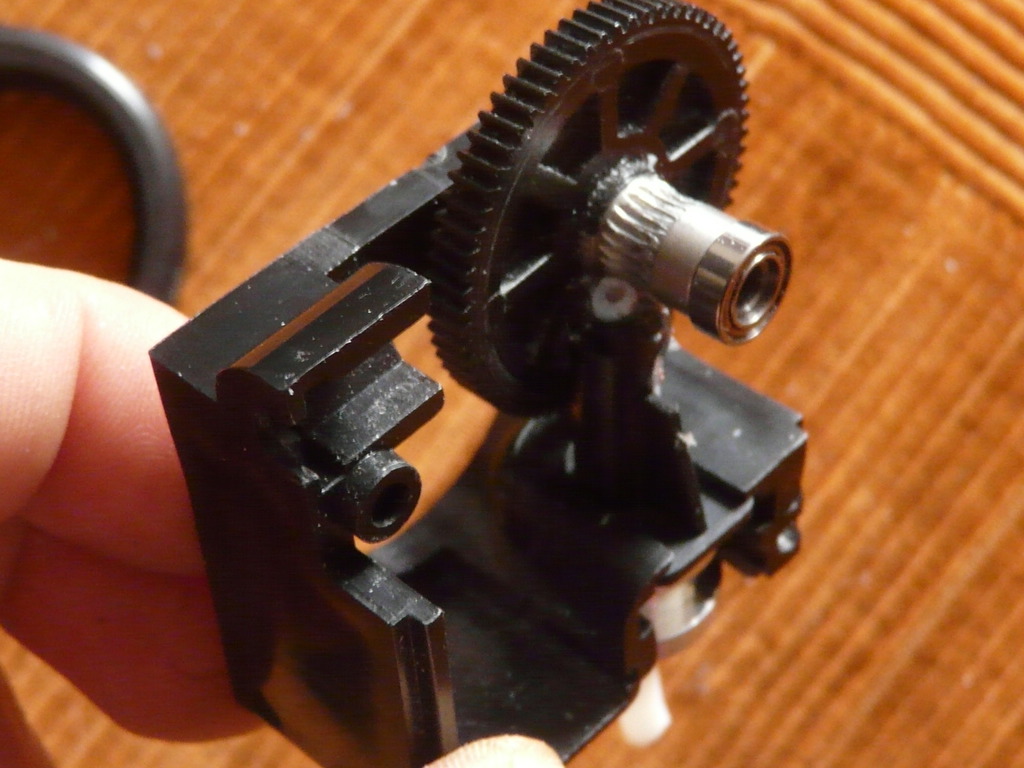

Update: After extensive testing with flexible and stiff materials, I'm pleased to report that it works flawlessly - inserting new filament is a breeze, no jams occur when the filament loses track of the hobbed area, and material breaks are eliminated even when pushing too hard. This upgrade is specifically designed for 1.75 mm filaments only. My cheap titan extruder clone has a subpar filament guidance system, which usually works well but can lead to issues with excessive pressure causing the filament to leave the hobbed area. If you're using an E3D Titan, this modification may not be of interest to you; however, both share a common weakness that makes printing with flexible filaments impossible. You can upgrade your titan extruder within an hour at a cost of just a few cents. This modification significantly eases filament handling. To perform the upgrade, you'll need: - A small PTFE tube with 2 mm inner diameter and 3 mm outer diameter (about 5 cm long), commonly used for inserting into nozzle throats. - Something to cut and resize the tube; I used a file, Dremel-like device, and knife. - The titan extruder clone comes with an interchangeable filament tube for 3 mm and 1.75 mm; you'll need the 3 mm tube. Here's how to proceed: 1. Insert the PTFE tube into the 3 mm tube of your titan extruder. If necessary, make it longer so it fits into the Bowden Adapter (another space where the filament could curl up). Leave about 3 - 4 mm extra on the upper side. 2. Secure the tube with glue, ensuring it doesn't obstruct the filament path. 3. Your setup should now resemble photo 4. 4. Cut the tube back to almost its original length at the idler (see photo 5). 5. Shorten the driver wheel's side, leaving about 2 - 3 mm standing; be cautious not to cut too much. Hold the pieces together to gauge your progress (photo 6). Note that this is not a straightforward horizontal cut; aim to leave as much material in the middle as possible. 6. It's acceptable if the tube still touches the hobbed area, but ensure the wheel can move freely. 7. If you have poor filament guidance for other materials, use the blue piece shown in photo 7 to prevent the filament from bypassing the hobbed area when applying pressure. You might be able to substitute this with a washer; my titan clone required a custom-made washer, which may differ for your extruder (photo 8). 8. Assemble everything as depicted in photo 7. 9. To prevent filament escape above the driver wheel, insert another piece of PTFE tube like in photo 8 and push it down until it touches the wheel; secure with glue (initially, a 4 mm tube might seem suitable, but it won't fit properly). 10. Print your flexible materials. 11. Consider donating to me generously. When cutting PTFE tubes, using scissors works better when there's filament inside.

With this file you will be able to print Cheap & simple Filament Guiding Upgrade for Titan Extruder & Clones - enables flexible Filament with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Cheap & simple Filament Guiding Upgrade for Titan Extruder & Clones - enables flexible Filament.