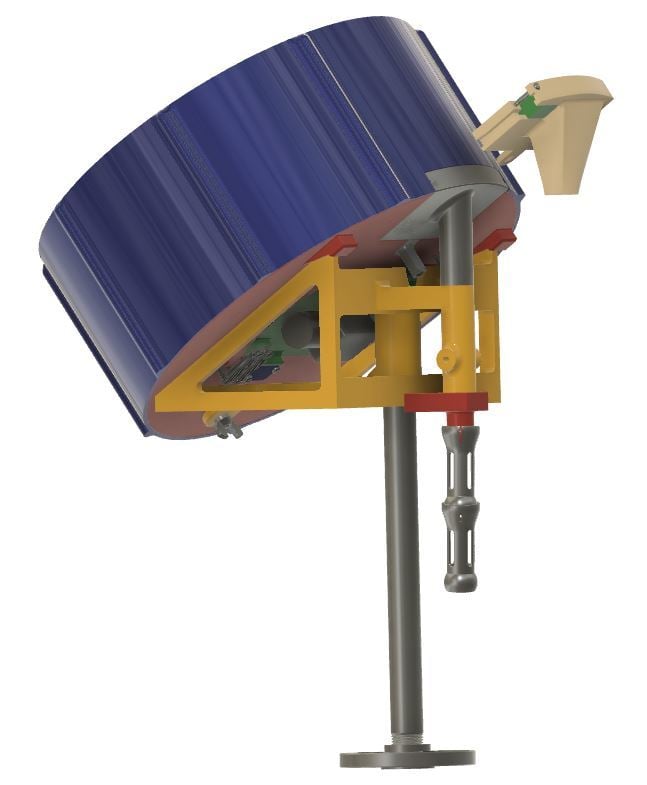

Case collator

thingiverse

My first major project involves creating something that can be easily replicated worldwide with minimal hardware. I aimed to use as little PLA as possible. To print larger items, you'll need a build plate measuring 30x30cm. With the exception of the shroud and frame, all parts can be printed without supports. Several cases have been successfully checked: The "Small Pistol Plate" works for 9mm Luger cartridges. The "Small Pistol Plate with spacer (for longer cases)" accommodates .38 Special and .357Magnum rounds. The "Rifle Plate" is compatible with 6.5x55 Swedish, .308Win, and 30-30 cartridges, although it required some adjustments. Next, I'm working on "shell plates" for various calibers, including .45ACP, long Colt, 45-70 Gov, 223, 30-30, and 12-gauge shotgun shells due to a new request. Considering the project's requirements, what else should be prioritized? The next development stages involve: 1. Implementing a cut-off switch (the frame model already has optical holes). 2. Adding a counter with an LCD display using either Raspi or Arduino. 3. Introducing speed control. For the required "gear motor," I recommend searching for something similar to this eBay search: "gear + motor + 12v +2rpm." For example, you can find suitable motors on eBay item number:302991374503 or Amazon's Greartisan DC 12V 120RPM Turbo Worm Geared Motor High Torque Turbine Worm Gear Box Reduction Motor 6mm Shaft JSX69-370. These motors are inexpensive, priced around $7-$8. On May 18th, I updated the drive adapter to accommodate a M4 Nut and extended its height by 15mm. On May 30th, I added an adapter connecting to the frame and the "flex tube." The flex tube was printed on my SLA printer, and it works impressively well. To enhance sturdiness or stability, I experimented with two options: using a simple cable tie to improve clamping or applying a single drop of superglue in the joints. Both methods yield excellent results. The "flex tube" can handle most handgun shells as well as larger cartridges like the .300WIN MAG or the shell for the Mosin-Nagant (7.72x54). However, with large shells, it's necessary to reduce the bend angle from its maximum 23° travel. On June 6th, I updated the drive adapter to make it printable on a SLA printer in a hollow mode with 2.5mm wall thickness. I also created a design for the "large Pistol Plate," which is suitable for .45ACP and can accommodate large revolver cases like 44Rem alongside small rifle cartridges like .222 or .223. On July 4th, I designed a new flex tube to ensure better grip and added the motor mount design drawing with the frequently requested hole pattern.

With this file you will be able to print Case collator with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Case collator.