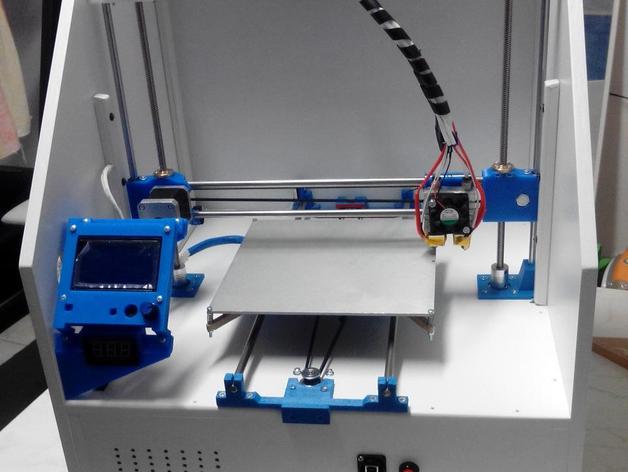

Cartesian 3D Printer

thingiverse

Cartesian Dual 3D Printer. The Z-axis is equipped with two motors and lead screws for precise control. Ramps, Mega2560, five DRV8825 drivers, an LCD display with a 12864 resolution, and an ATX power supply are all part of the system. Six Nema17 motors provide the necessary power, while two mechanical end-stops ensure safety and precision. Lead screws with an 8mm pitch and 2mm thread size offer high accuracy and reliability. Two spring couplers, each measuring 5 x 8mm, facilitate smooth operation and minimize vibration. A GT2 belt connects the pulleys for a precise and consistent motion. Twenty-tooth GT2 pulleys ensure seamless movement and minimal friction. Four 608RS bearings provide stability and support for the printer's mechanisms. The MK3 aluminum heat-bed offers exceptional thermal performance and durability. An extruder feed gear with a 40T output diameter of 11mm and an input diameter of 5mm ensures efficient material flow. The total cost is approximately 320 euros. MDF pieces, measuring 12mm thick, are used for construction. Dimensions include two pieces measuring 450 x 450mm, two pieces measuring 100 x 450mm, two pieces measuring 100 x 426mm, two pieces measuring 450 x 500mm (which can be modified to 450 x 515mm for increased Z height), one piece measuring 120 x 450mm, and one piece measuring 346 x 450mm. The total cost of the MDF pieces is 9.40 euros. If you modify the two 450 x 500mm pieces to 450 x 515mm, you will gain more Z height. When using 12mm wood to hold the extruder motors, it's essential to make the wood 6-8mm thin or cut a slot where the motors connect with the wood. Alternatively, you can use a thinner piece of wood. I'm still considering how to implement the Z-axis end-stop and height mechanism. A dual Bowden extruder system is used, along with a homemade hotend that's still under development and testing. The print build volume is 200 x 200 x 187mm, but with some modifications, it can be increased by about 10mm. This can be achieved by using thinner bed wood supporters or smaller springs. For now, everything works great except for the hotend, which needs further modification and testing. I have a temperature monitor to keep an eye on the electronic compartment's performance. The Marlin firmware is available in a RAR file, but you'll need to adjust the feedrates and acceleration according to your specific motor setup. Printer Settings: Brand: RepRap Printer: SmartRapCore Rafts: Doesn't Matter Supports: Doesn't Matter Resolution: 0.25 Infill: 40 Notes: PLA blue PET-G white, simply because I had it on hand. Very few supports are needed. Custom Section: A small test of movement is included for your reference.

With this file you will be able to print Cartesian 3D Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Cartesian 3D Printer.