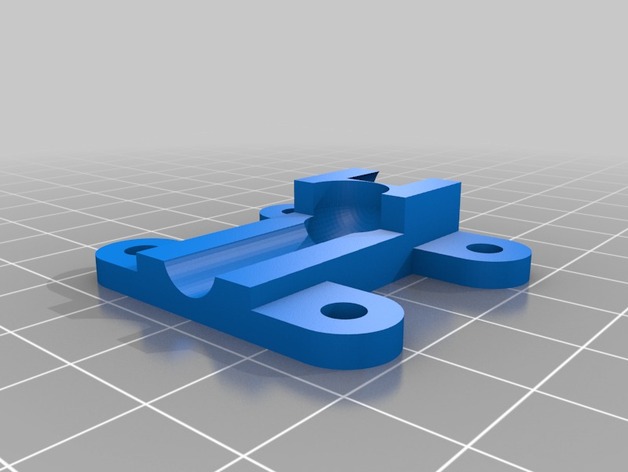

Carbon fiber magnetic ball joint jig for the Cerberus, Cerberus Pup, and other Rostocks

thingiverse

This tool constructs consistent length magnetic joint arms for Cerberus, Cerberus Pup, and Rostock deltabot printers. Requirements include 3/8" steel bearings, 3/8" neodymium magnets, and carbon fiber shafts like arrow shafts. Use strong metal-to-carbon adhesive, such as Loctite Metal / Concrete epoxy or JB Weld. Mount the printed parts on a wooden base with screws. Note that the STL uses 7.28mm diameter carbon fiber rods; adjust accordingly if different. Follow the assembly instructions, which detail a method to avoid epoxy mess by gluing one ball at a time: insert a magnet into each jig piece, put a ball in one jig (not both), mix a small amount of two-part epoxy, and carefully apply it inside the carbon fiber rod. Position the jig vertically so the ball rests at the bottom. Insert the rod's end with epoxy against the ball, ensuring no squeeze-out. After 30-60 minutes, perform the process on the second ball by rotating the jig. This method uses gravity to help the epoxy adhere to the ball effectively.

With this file you will be able to print Carbon fiber magnetic ball joint jig for the Cerberus, Cerberus Pup, and other Rostocks with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Carbon fiber magnetic ball joint jig for the Cerberus, Cerberus Pup, and other Rostocks.