Campus Security Customisation Design

grabcad

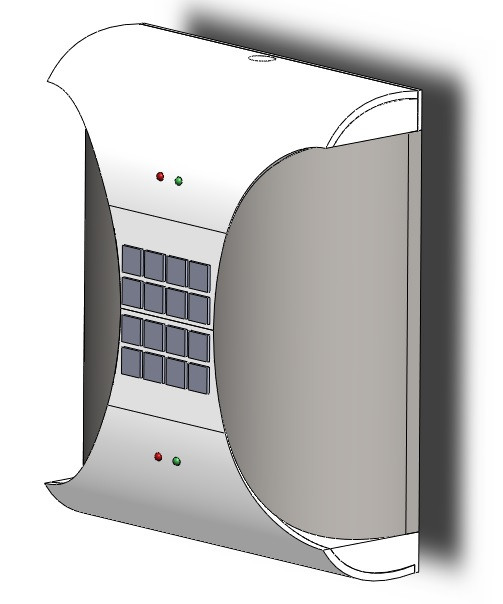

The design features a square measuring 150mm x 150mm with a 55mm upset, constructed from two identical plastic parts and a sheet metal casing. The metal casing can be manufactured using transfer die systems, although initially it may seem challenging. This casing can be pre-mounted by technical staff from the university, which should also incorporate a power entrance. Material options for the metal part include aluminum, stainless steel, or low-carbon steel; in the latter case, painting is required, with university colors preferred as an advantage. To reduce costs, both plastic parts are identical, and sealing material is applied to the contact point between plastic and metal components. The plastic part provides sufficient surface area for displaying the university logo, which can be made from polypropylene and colored if desired. Manufacturing this design may be complex, necessitating a two-parted injection die on a hot tip gated injection system for the die designer. The metal casing ensures complete accident protection, making it difficult for vandals to harm the electronics inside. While plastic parts can crack, they are challenging to break entirely. Electronic components have not been depicted separately but should be interchangeable for ease of replacement. In case of failure, university staff can replace the entire electronic blackbox with a spare and send the defective one for repair. The designer envisions using this design in their university and even creating a laboratory logo to adorn the access reader, potentially with a custom sticker.

With this file you will be able to print Campus Security Customisation Design with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Campus Security Customisation Design.