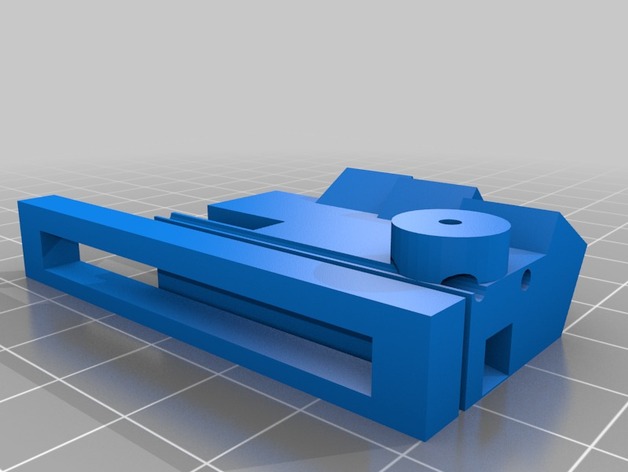

Calibration test shape V2

thingiverse

This design is created to verify a printer's capacity to print some of the most difficult features of e-NABLE Prosthetics. This model is a work in progress and has been shared for the purpose of discussion among users. Specific aspects being tested include: The ability to print overhangs at angles of 30, 45, and 60 degrees. 2mm tunnels that are both vertical and horizontal. A check should also be made to see if filament as small as 1.75mm can be printed through the tunnel. A bridge across a ramp with a nearly flat surface is tested by printing it 5mm wide at an angle of just 10 degrees. The circle shape on the model should verify x/y calibration and the ability to print smooth curves. The overall dimensions of the shape are 40mm in width, 20mm in height, and 10mm in depth. It should be checked to see if axis scaling has been done correctly. A flat surface at the top with no gaps is essential, so checks must also be made on filament fill levels and diameter size.

With this file you will be able to print Calibration test shape V2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Calibration test shape V2.